Need something? 3D print it!

Using advanced additive manufacturing technologies, Assoc Prof Yeong Wai Yee of NTU's School of Mechanical and Aerospace Engineering designs a new generation of smart devices from high performance materials.

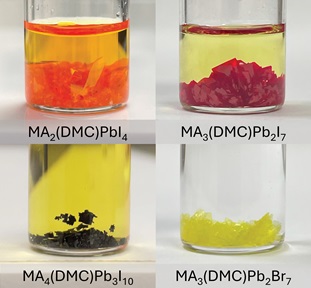

Figure 1: 3D printed implant with lattice structure design fabricated with selective laser melting technique.

3D printing, also known as additive manufacturing, is an automated process where materials are added layer by layer to form intricate structures with tailored performance that cannot be achieved using conventional fabrication methods. Currently, we are developing high-performance materials and multifunctional structures through advanced manufacturing technologies such as metal printing, composite printing and electronics printing.

Super strong metals straight from the printer

My group has successfully designed and printed customised orthopaedic implants made from titanium-tantalum (Ti-Ta) (Figure 1). We used an in situ alloying approach that enables rapid customisation of the composition of the alloys while keeping the advantages of 3D printing such as mass customisation. Due to their better fit and material properties, the implants produced by additive manufacturing also have the potential for better performance compared to conventional implants. We have filed for a patent for our technology, which has led to several collaborations within Singapore and overseas.

materials, allowing us to create anatomical models with tissue-mimicking properties.

Increasing the freedom of design

Multifunctional electronics

Making possible the creation of high-performance materials, 3D printing of electronics components is achieved by printing functional electronic components such as circuits and sensors directly on the surface of structures to achieve various functions such as heating, temperature sensing, signal transmission and health monitoring.

We have worked with a local start-up, Flare Dynamics Pte Ltd, to replace the conventional copper wire by 3D printing silver traces onto the surface of a drone’s structure to achieve weight reduction (Figure 3). This project not only demonstrates a new way of fabricating electronics, but also creates opportunities to design the next generation of electronics.

Digitalising 3D printing

I foresee that this new generation of smart devices, made from high-performance materials with 3D printing as the enabling technology, will play a critical role in the future of manufacturing in Industry 4.0.

By Yeong Wai Yee

Award-winning 3D printing innovator Assoc Prof Yeong Wai Yee is Programme Director (3D Printing) in the HP-NTU Digital Manufacturing Corporate Laboratory, Programme Director (Aerospace & Defence) in the Singapore Centre for 3D Printing, and Associate Chair (Students) at NTU’s School of Mechanical and Aerospace Engineering. You can read about her research in Composites Part B: Engineering (2021), DOI: 10.1016/j.compositesb.2021.108840; Artificial Intelligence Review (2021), DOI: 10.1007/s10462-020-09876-9; Journal of the Mechanical Behavior of Biomedical Materials (2020), DOI: 10.1016/j.jmbbm.2020.103775; Sensors and Actuators B: Chemical (2018), DOI: 10.1016/j.snb.2017.12.127; and Anatomical Sciences Education (2017), DOI: 10.1002/ase.1703; or watch a video on 3D printing of electronics components—a collaboration of Assoc Prof Yeong and Singapore start-up Flare Dynamics Pte Ltd—on bit.ly/PF193Dprintelectronics.

The article appeared first in NTU's research & innovation magazine Pushing Frontiers (issue #19, August 2021).

.tmb-listing.jpg?Culture=en&sfvrsn=29c7e020_1)

.tmb-listing.jpg?Culture=en&sfvrsn=55153609_1)