Rock Preparation Laboratory

The aim of the Volcanic Petrology group is to conduct fundamental research on magmatic processes and rocks from active volcanoes, toward better understanding and forecasting of volcanic eruptions. Facilities include a sawing, lapping and polishing equipment to be used to make a high quality thin sections.

Equipment: Laboratory Micro Cutting Machine

Model/Brand: CUTLAM® Micro 1.1

Specifications

- Wheel Ø: 75 to 150 mm

- Shaft Ø: 12,7 mm

- Standard flanges Ø: 50 mm

- Lateral arm displacement: Stroke 25 mm (accuracy 0,02 mm)

- Lubrication/Cooling: Recirculation system, 10 litres, 800 L/ hour pump driven by the machine

- Rotational speed: Variable, from 50 to 1500 rpm

Applications

For precision cuts of the most sensitive materials

Equipment: Slicing Machine

Model/Brand: BROTLAB 1.02.15

Specifications

- Thickness adjustment via screw controlled by max travel micrometer 30 mm. Adjustment accuracy: 0.01 mm.

- 100 microns cutoff from glass bonded samples

- Ø175 diamond disc

- Recirculating cutting fluid tank: Capacity 25 litres

Applications

Study of materials in geology often forces to collect thin sections or slice samples on their object holders before lapping or polishing, for examination in optical microscopy, microphotography, spectrometry, microprobe, scanning or transmission microscopy

Equipment: Polishing Machine

Model/Brand: BROTLAB 1.03.17

Specifications

- Polishing machine with variable speed from 25 to 200 Rpm, high torque at low speed without vibrations

- Display for Rpm of the plate and effective torque

- Timer for polishing time 1 to 60 minutes

- Sample-holder for 3 samples (or 5 in option) ensuring 3 regular motions, to the preparation, without inversion jerk or push-pull.

Applications

High quality polishing while maintaining perfect flatness using diamond/aluminium compounds installed on a synthetic plate

Equipment: Polishing and Grinding Machine

Model/Brand: BUEHLER

Specifications

- Plate Ø 250 mm

- Variable RPM 0-600

Applications

This simple and robust turn-table allows the manual grinding and polishing

Equipment: Polarising Microscope

Model/Brand: SP-1500 XP Brunel

Specifications

- Full polarising specification and is available in both transmitted or transmitted and incident (ore) illumination

- Quadruple objective turret with x4, x10, x40 and x60 planachromatic long working distance

Applications

Polarising microscope

Equipment: Low Speed Saw

Model/Brand: IsoMet BUEHLER

Specifications

- Cutting Capacity: 1.50[in], 38.00[mm]

- Wheel Diameter: 5.00[in]

- Cut Action: Gravity Fed Chop

- RPM @60: Hz: 300

Applications

A precision sectioning saw that is designed for cutting various types of materials with minimal deformation.

Equipment: Lapping Machine for Thin Sections

Model/Brand: BROTLAB 1.03.16

Specifications

- Allows up to 12 samples to be taken simultaneously.

- Final thickness is adjusted using 3 micrometers graduated in 1/100 mm

Applications

Machine for automatic thinning at a specified thickness of object glass slides and rocks glued to glass slides (thin blades). It allows the heels to be used before sticking them to the glass slides.

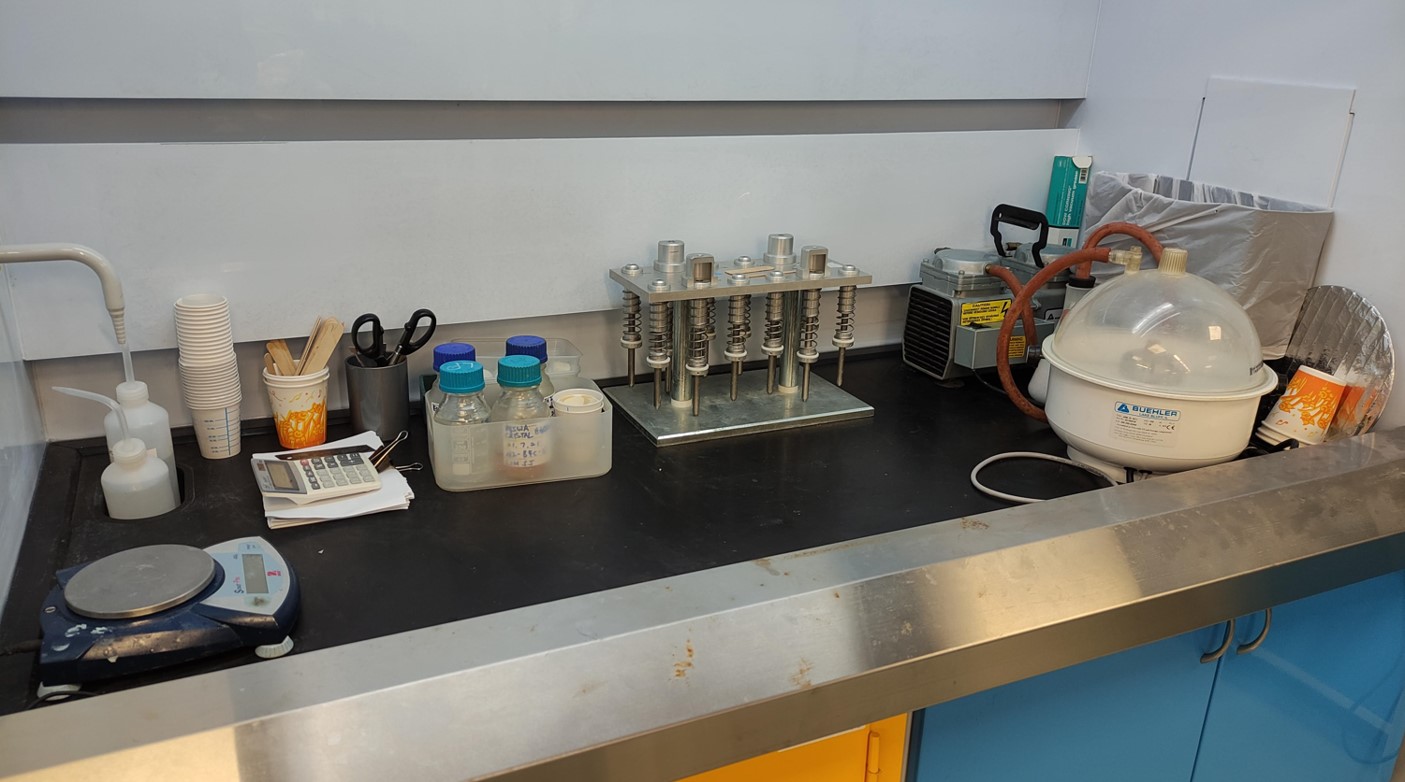

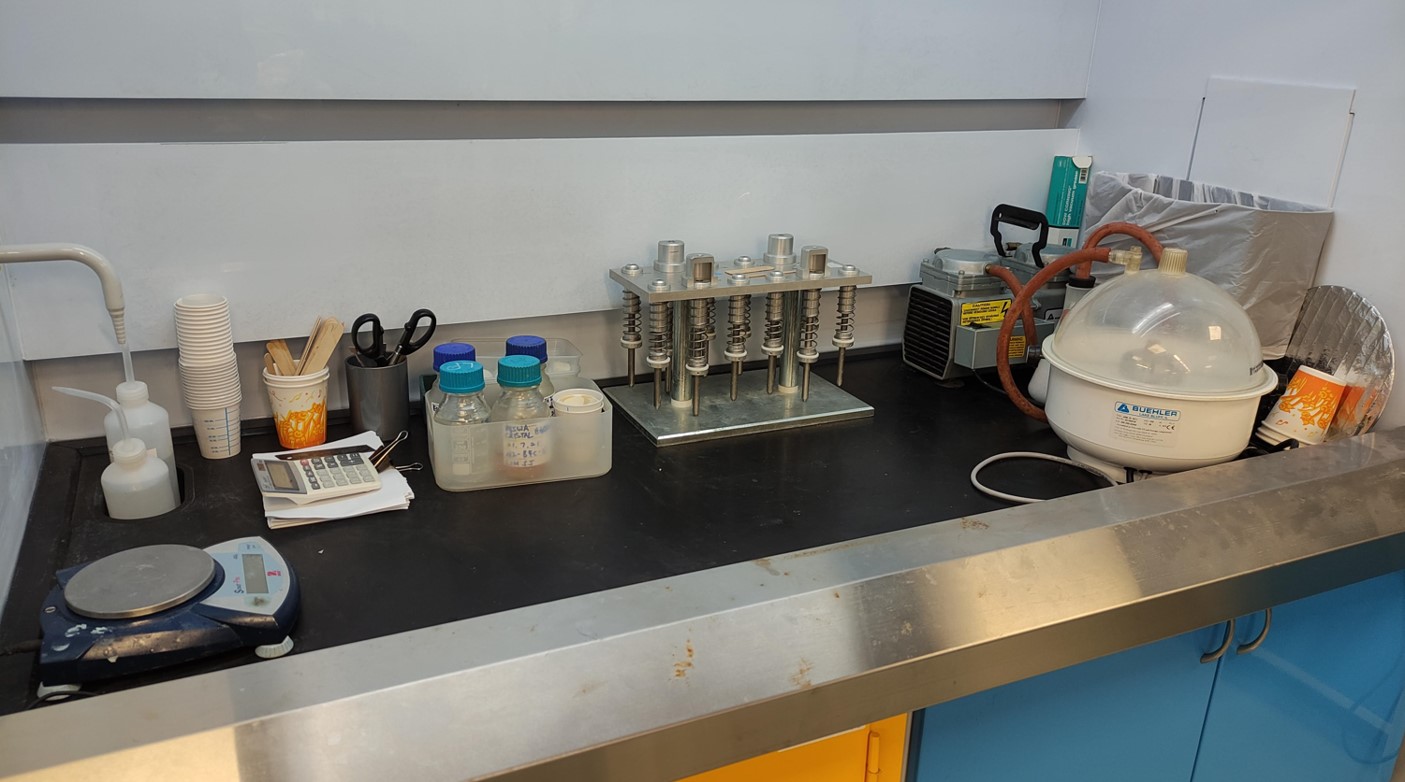

Equipment: PetroBond Thin Section Bonding Fixture

Model/Brand: Buehler

Specifications

- Controls adhesive thickness by evenly distributing adhesive

- Holds up to 12 slides

Applications

Equipment: Cast N' Vac 1000 Vacuum System

Model/Brand: Buehlerv

Specifications

- Large chamber for multiple samples

- Unique tilting dispensing mechanism

- Built-in synchronous motor and rotating turn table

Applications

Vacuum impregnation systems for use with epoxy mounting. The Cast N’ Vac removes trapped air from mounting material, and fills voids in the specimen. This enhances edge retention and supports delicate and friable samples