Welcome Message

Read moreAbout us

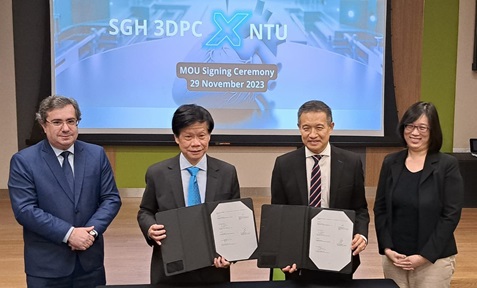

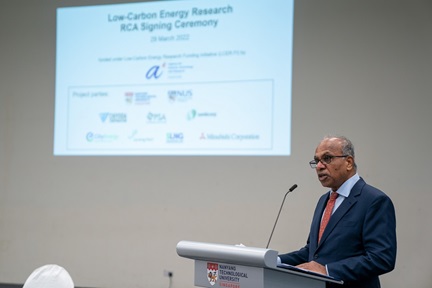

NTU's industry partnerships are integral to its commitment to innovation and practical impact. Through dynamic collaborations, the Vice President (Industry) Office engages with industry leaders to drive cutting-edge research, facilitate technology transfer, align academic programs with real-world demands, and develop diverse talent pipelines.NTU sustains Industry Partnerships with over 700 companies to-date with the largest engagements through the Corporate Laboratories that include major companies such as Continental, Nanofilm Technologies, Singtel and Rolls Royce.

GAIN - Global Alliance of Industry @ NTU provides an additional platform to catalyse inter-companies research collaboration supported by breadth and depth of research capabilities residing within the University.

Our commitment

To support the University’s ambition to further strengthen her rapidly growing industry engagements to benefit research and education

To advance NTU-Industry collaboration in education and research at University level

To address global challenges and national priorities through co-creation of future-ready talent, achievement of breakthroughs and generation of economic benefits

Industry Lab Launches

News Highlights

Read moreHP-NTU Corporate Lab Showcases R&D Innovations; Announces Digital Manufacturing Skills Development Programme for the Fourth Industrial Revolution

Researchers from global technology leader HP Inc. and Nanyang Technological University, Singapore (NTU Singapore) in the HP-NTU Digital Manufacturing Corporate Lab today showcased digital manufacturing technologies set to make manufacturing and supply chain operations more efficient, cost-effective and sustainable.

Among them are intelligent design software tools that automate advanced customisation, as well as supply chain models that enable faster time to market while lowering carbon footprint.

The lab also unveiled a new skills development programme aimed at helping Singapore train and upskill its talents in additive manufacturing and digital design – from fundamentals of additive manufacturing and digital product designs to data management and automation, under the SkillsFuture programme.

With the intelligent design software tools being developed by the lab, engineers can customise and optimise their materials’ mechanical properties more effectively. The automated tools let designers achieve designs that have the best combination of properties to achieve the desired strength, flexibility, and weight. Imagine a customised, lightweight 3D-printed plastic cast aimed at giving patients greater comfort and fit.

These proofs-of-concept and technology demonstrations were showcased at the official opening of the HP-NTU Digital Manufacturing Corporate Lab today. The event was also part of HP’s 50th Anniversary celebration of its presence in Singapore. HP started with a small assembly factory in Singapore in 1970. Today’s HP’s Singapore footprint includes its Greater Asia region headquarters, global supply chain control towers, print R&D centres of excellence, as well as manufacturing facilities.

The research partnership between NTU Singapore, HP Inc. and the National Research Foundation Singapore (NRF), was first announced in October 2018.

- Industry

.png?sfvrsn=a368937b_2)