The serial inventor

In this interview, Prof Louis Phee, Dean of NTU's College of Engineering, shares his thoughts on how Industry 4.0 technologies will revolutionise medical and social care in the future.

How best to foster a culture of innovation among students and faculty is something Prof Louis Phee thinks about deeply in his capacity as Dean of NTU’s College of Engineering. His efforts have certainly paid off. NTU is now ranked #1 in the world in fields such as nanoscience and nanotechnology, and materials science, according to the latest U.S. News and World Report.

But the Tan Chin Tuan Centennial Professor in Mechanical Engineering is also an inventor at heart. Prof Phee’s research team designs robots that improve medical treatments and surgical procedures, an effort which he says combines his lifelong passion for medicine and engineering.

endoluminal access surgical efficacy system, the world’s first robotic flexible endoscopy system for minimally invasive surgeries.

Prof Phee has since co-founded several companies, including two NTU start-ups—EndoMaster Pte Ltd, to commercialise the endoscopy system, and EndoPil Pte Ltd, to commercialise a balloon-releasing weight management capsule.

Here, he shares his vision for how Industry 4.0 technologies can change the way medical and social care is delivered, and the qualities he believes are necessary for entrepreneurial researchers.

Q: You are a force in NTU’s rapid growth as a university in Industry 4.0 technologies. Any thoughts on what gives NTU the edge in areas such as nanotechnology?

A: NTU has been ranked first in the world in nanotechnology. The first reason for this success is that we have a critical mass of exceptional professors, which helps to draw other top scientists in this area to NTU.

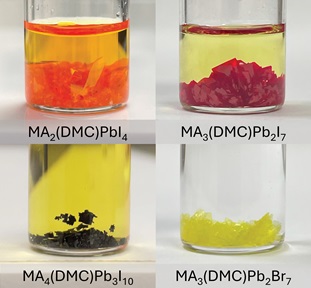

The second reason is, we have great facilities, such as the Facility for Analysis, Characterisation, Testing and Simulation, with state-of-the-art microscopes and imaging equipment. Access to these facilities and equipment allows us to conduct top-notch research in materials and nanomaterials sciences that results in improvements to our lives, for instance, better healthcare.

Q: What opportunities will Industry 4.0 technologies such as robotics and artificial intelligence (AI) create in manufacturing?

A: Industry 4.0 technologies combine for the first time the physical and cyber worlds with the biological world, and this will drastically change all industries, especially manufacturing. So far, products have been manufactured in high volume and low mix. Going forward, we will have more personalisation, which means low-volume high-mix production.

customised batches.

As a result, we will have more specialised factories spread across the globe for decentralised production of personalised products, instead of production in one or a few factories. Products will then be combined in centralised assembly points, which will lower costs.

Q: How will technological developments help societies cope with a rapidly ageing population, and how has NTU contributed in ageing research?

People all over the world are leading longer lives and populations are increasingly ageing. To help Singapore prepare for this so-called silver tsunami, NTU has placed an emphasis on Industry 4.0 technologies, including robotics, AI and assistive technologies, which can support the elderly in staying healthy and fit.

AI can keep people connected to friends and family, and help to monitor the physical and mental well-being of independently living elderly. For example, researchers at the Joint NTUUBC Research Centre of Excellence in Active Living for the Elderly—NTU’s collaboration with Canada’s University of British Columbia—are developing sensors that pick up on signals, alerting family or caregivers if no movement has been detected for an extended period or if the fridge hasn’t been opened in the morning, while maintaining the elderly’s privacy.

strength, and tie the data to brain function. Exoskeletons can help patients who have lost all strength in their legs or frail people to stand upright and walk, which is very important for people’s dignity. You also need to make sure that the cognitive capabilities of the elderly remain sharp. To this end, researchers in the Ageing Research Institute for Society and Education and other centres in NTU are developing games for the elderly to train their minds and help detect or fend off the onset of dementia.

Q: As automation and robots become increasingly prevalent in everyday life, what are the new challenges that have emerged? How is the College of Engineering addressing these challenges?

A: For the longest time, mankind has been inventing and developing machines without enough consideration of the user. In my opinion, the biggest challenge is the adoption of these new technologies, which will take time and a better understanding of its intended users.

To give you an example in my field of medical robotics: When the first surgical robots were invented about 20 years ago, patients refused to have their surgeries carried out by a robot. But as we slowly prove the benefits of surgical robots, in today’s context, more people will opt for the robot over the surgeon because it is more accurate.

To overcome people’s scepticism, engineers must work closely with researchers in social sciences, humanities and business to develop and roll out technologies in ways people are comfortable with, and affordably.

All this boils down to working across disciplines. In NTU we are addressing this through a compulsory interdisciplinary collaborative curriculum in which all freshmen across all disciplines will learn about global challenges like climate change, sustainability and entrepreneurship together. Meeting students and faculty from other disciplines will help to break down barriers right from the start for future interdisciplinary collaborations.

Q: What skills do students in the College of Engineering need to pick up to become leaders in Industry 4.0?

A: NTU is developing a culture of entrepreneurship to help our students become less risk averse. In tomorrow’s job market, students will need to have good depth in at least one discipline, but—equally important—they need to have good breadth across many disciplines.

A business student, for example, needs to know a bit of programming, natural sciences and so on. Most importantly, students need to dare to try something and dare to fail. It’s going to take a culture change, including developing resilience towards failure. We also need to find more success stories to encourage our students towards entrepreneurial endeavours.

Q: As co-founder of two NTU start-ups, what advice do you have for budding student and faculty entrepreneurs?

A: Entrepreneurship is all about passion. Even though I am pushing for innovation in NTU, I recognise that innovation and entrepreneurship is not for everyone.

I encourage faculty and students to do some soul-searching first, to ask themselves whether they have the passion to embark on this journey, because it is going to be a rollercoaster ride and you can’t just try it for fun—you need to give it your all.

The article appeared first in NTU's research & innovation magazine Pushing Frontiers (issue #19, August 2021).

.tmb-listing.jpg?Culture=en&sfvrsn=29c7e020_1)

.tmb-listing.jpg?Culture=en&sfvrsn=55153609_1)