Research Facilities and Equipment

The School of Materials Science and Engineering (MSE) at NTU is home to a comprehensive range of sophisticated research infrastructure, supporting advanced innovation in materials synthesis, testing, and characterisation. These facilities form the backbone of our internationally acclaimed research and enable breakthroughs across sectors such as semiconductors, energy, biomedical materials, and sustainable manufacturing.

Recognised as one of the world’s leading materials science and engineering institutions, we provide the NTU community — as well as partners from industry and government — access to specialised equipment, technical expertise, and collaborative research opportunities. We welcome expressions of interest from organisations keen to tap into our capabilities. While our foremost priority remains supporting education and academic research, we are open to exploring industry collaborations where feasible. All proposals are carefully reviewed based on facility availability, alignment with research goals, and technical suitability.

Common Use Cases:

Failure analysis: Diagnose mechanical, thermal, or structural breakdowns

Third-party testing: Independent verification of component quality and standards compliance

Training and technical upskilling: Joint workshops or hands-on capability building for engineers and technicians

2ca55129-7241-4851-8765-bb983d6e3d13.png?sfvrsn=b9571891_5)

How Industry Partners Work With Us

We offer flexible models to meet different project scales, timelines, and confidentiality needs:

1. Collaborative R&D Projects

Work with our faculty and researchers to co-develop solutions aligned with your innovation goals. Suitable for long-term development or pilot-scale studies.

2. Contract Research & Testing

Commission us to conduct tests, simulations, or failure analysis based on pre-agreed scopes. A cost-effective option for specific, outcome-driven needs.

3. Fee-for-Use Access (Limited basis)

Industry partners may access selected MSE research instruments and testing equipment on a pay-per-use basis for internal R&D, product testing, or technical validation.

To ensure safe and effective use of our facilities, external users must be certified by NTU MSE for independent operation of complex equipment. Certification includes hands-on training and a short assessment. Please note that technical staff assistance may not always be available during your booked slots, and usage is subject to lab availability and safety protocols.

This access model is best suited for:

- Companies with experienced technical staff

- Repeat users familiar with similar instrumentation

- Short-term material verification and data gathering

For specialised equipment requiring supervision, we may recommend contract testing or collaborative R&D as an alternative.

4. Talent & Infrastructure Bundles

Combine access to equipment with our faculty or student research talent under final year, postgraduate, or work-study schemes – ideal for resource-constrained R&D teams.

5. Training Workshops & Facility Familiarisation

Customised training for your engineering or technical staff on selected equipment, techniques, or testing protocols.

Why Work With Us

Access specialised research tools typically only available in academic or national research institutions – without the capital investment or long-term equipment maintenance costs. Ideal for feasibility studies, one-off validations, or bridging internal capacity gaps.

Expertise-Backed Access

Our equipment is operated and maintained by trained specialists and research staff. Whether you’re seeking data, interpretation, or method development, you’ll benefit from the guidance of faculty and technical experts who understand both the science and your industry context.

Comprehensive Materials Analysis in One Place

From thermal and mechanical testing to electrical, optical, and microstructural analysis, our suite of instruments allows for full-spectrum material evaluation – minimising outsourcing and accelerating turnaround.

Flexible Access Models

We offer multiple engagement options to suit your needs:

- Fee-for-use access (where available)

- Joint R&D with faculty teams

- Contract testing & data generation

- Talent + equipment bundles (e.g. student projects using in-house tools)

- Training Workshops & Facility Familiarisation

Customisable, Confidential, and Collaborative

All industry access is evaluated for technical alignment and capacity. Where partnerships proceed, we work closely with you to define scopes, timelines, and IP/confidentiality arrangements that meet your project needs.

Application-Focused and Outcome-Oriented

We understand your priority is actionable data and results. Whether you’re optimising a process, qualifying a material, or solving a production issue, our goal is to help you move forward with clarity and confidence.

Our Laboratories

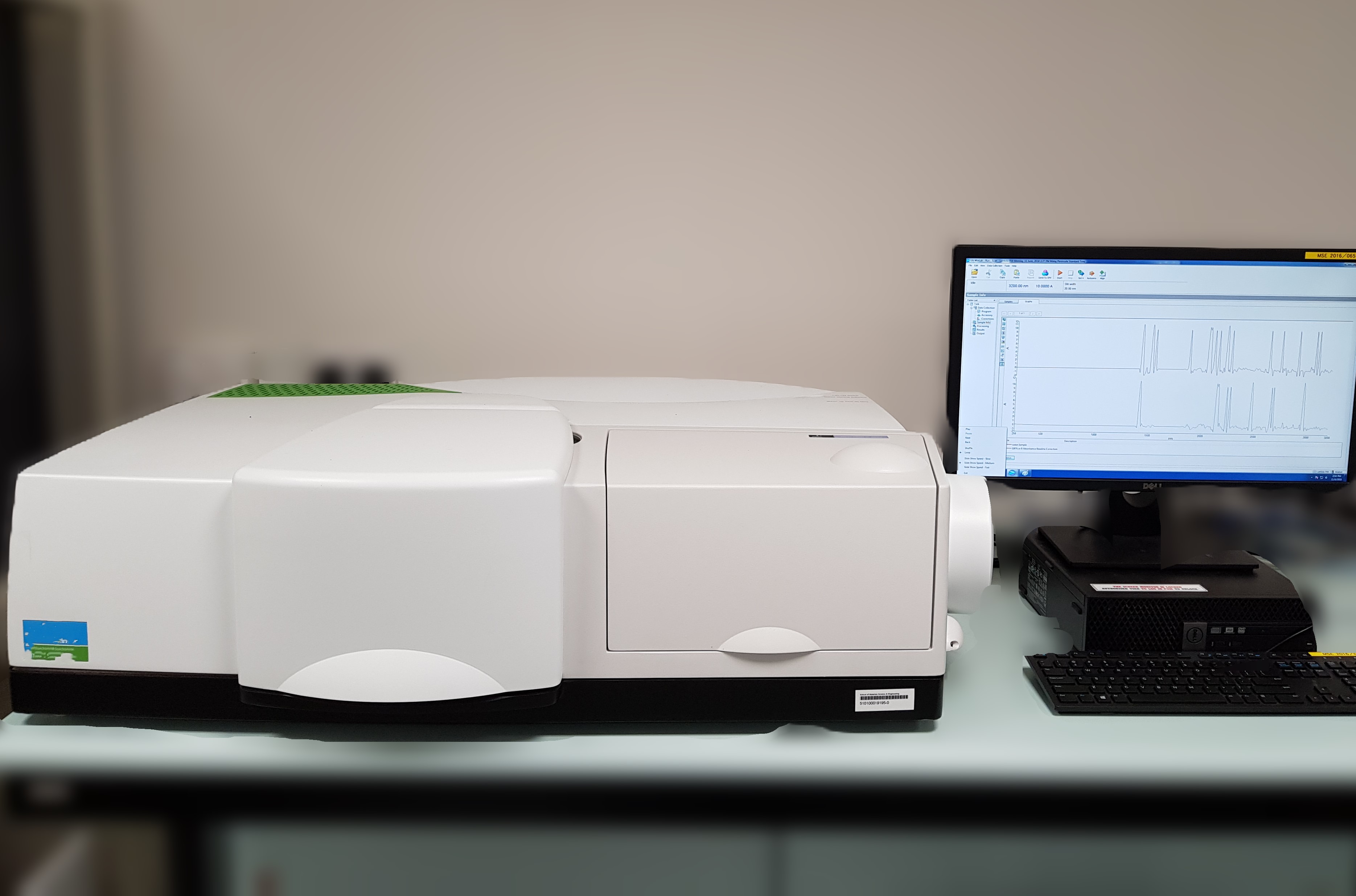

- Confocal Raman Spectrometer

- Fluorescence Spectrophotometer

- Fourier Transform Infrared (FTIR) Spectrometer

- Fourier Transform Raman Spectrometer

- Thermogravimetric Analyser - Infrared Spectrometer

- UV-Vis NIR Spectrophotometer

- Inductively coupled plasma - Optical Emission Spectrometer (ICP-OES)

- Matrix Assisted Laser Desorption Ionisation-Time of Flight-Mass Spectrometer

- Differential Scanning Calorimeter

- Modulated Differential Scanning Calorimeter

- Nano Differential Scanning Calorimeter

- Nano Isothermal Titration Calorimeter

- Thermogravimetric Analysers

Spectrometers and Spectrophotometers

Mass Spectrometers

Thermal Analysers

- Atomic Force Microscope

- Fourier Transform Infrared (FTIR) Microscope

- Polarizing Microscope

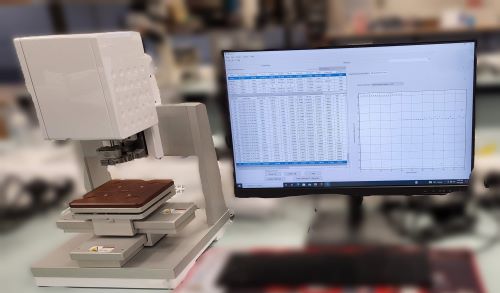

- Optical Contact Angle Measuring System

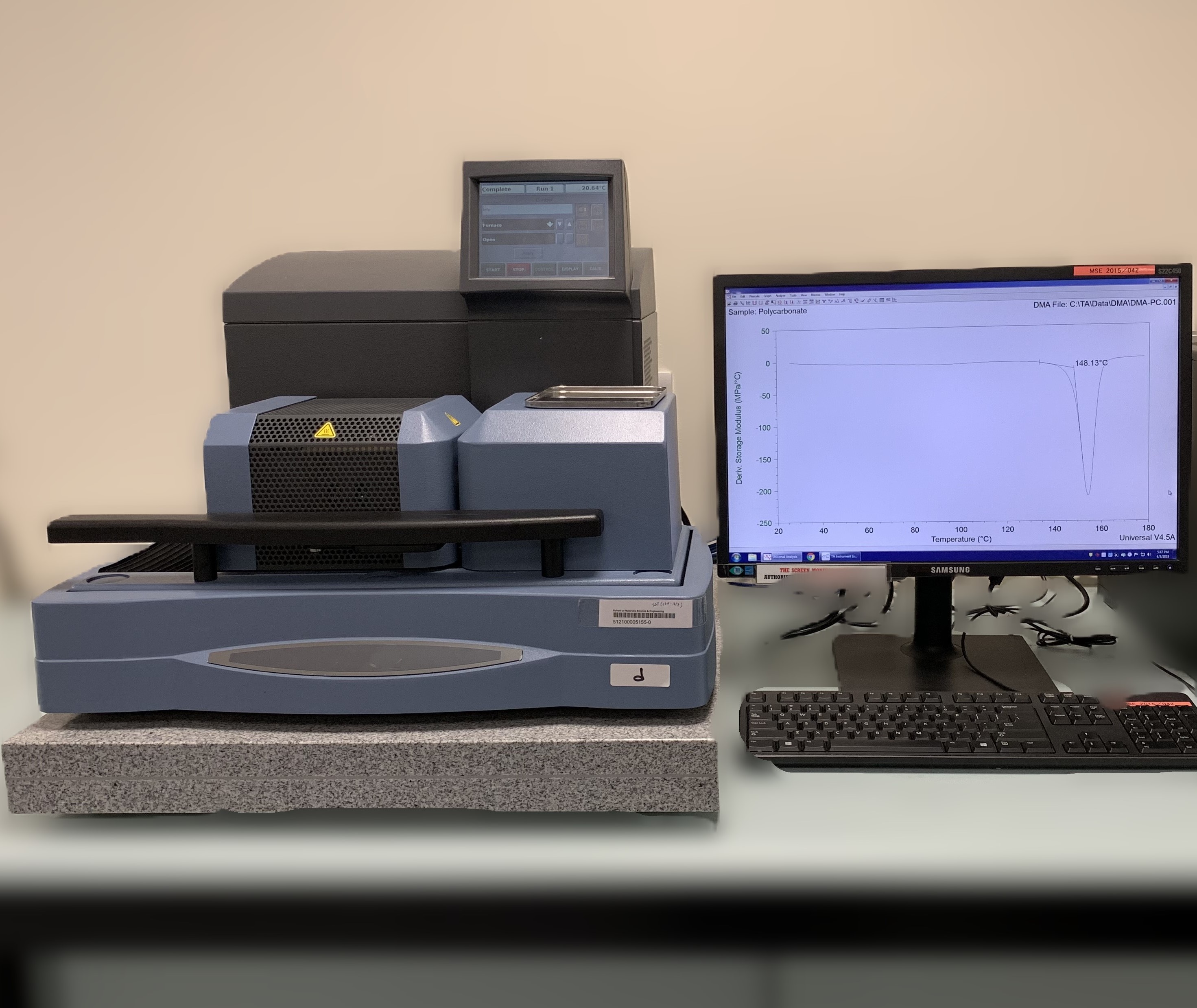

- Dynamic Mechanical Analyser

- Dynamic Mechanical Tester

- Static Mechanical Tester

Optical Contact Angle Measuring System

Mechanical Test Instruments

- Abrasive Cutter

- Grinder/Polishers

- Hot Mount Press

- Precision Saw

- 3D Printer

- Turbo Sputter Coater

- Physical Property Measurement System

- Densimeter

- Ellipsometer

- Resistivity / Sheet resistance Measurement System

- Surface Area and Porosity Analyzer

- Nanoparticle Zeta potential Analyzer

- Particle size Analyzer

- Gas Pycnometer

Sample Preparation Systems

Physical Property Measurement Instruments

Electrical and Magnetic Property Measurement Instruments

- Inverted Microscope

- Upright Microscope

- Stereo Zoom

- Digital Microscope

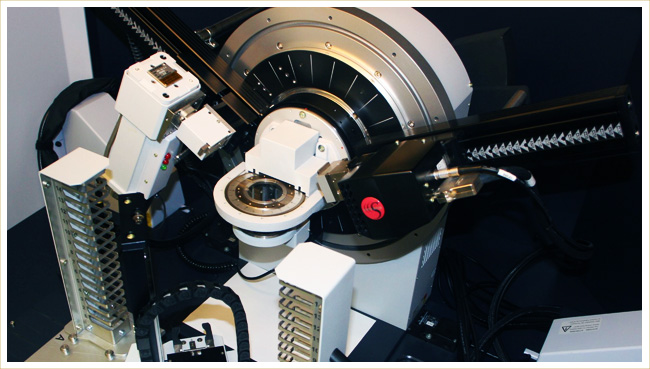

Electron microscopy, microanalysis & x-ray diffraction analysis

Thermal Mechanical Analysers

0decabc8-5b87-49fa-8376-44a652c20e1b.jpg?sfvrsn=5b93954c_10)

Microscope Imaging & Optical Systems

Affiliated Research Institutes, Centres & Facilities

| Computational / Characterisation Materials Science | Facility for Analysis Characterisation Testing and Simulation F.A.C.T.S. |

| Energy (Generation & Storage) | Energy Research Institute@NTU Singapore Energy Centre (SgEC) |

| Biomaterials / Biological Materials | Institute for Digital Molecular Analytics and Science (IDMxS) Mission • To enable the world of IT to sense the biological world • To create a world-leading platform for new analytical science that will advance the boundary of possibilities between living systems and engineered technologies Singapore Centre for Environmental Life Sciences Engineering (SCELSE) |

| Bioinspired / Sustainable Materials | Centre for Sustainable Materials (SUSMAT – B2R2) Mission • To deploy multi-faceted Materials Science expertise to develop bioinspired and eco-friendly solutions in critical sustainability areas • To contribute to circular economy through recycling and valorization of waste generated by synthetic materials and the agro-food sector RGE-NTU Sustainable Textile Research Centre (SusTex) Mission • To be the global knowledge leader in developing sustainable technologies for textile recycling in an urban setting, with a focus on viscose rayon, cotton, and mixed textile recycling Singapore CEA Alliance for Research in Circular Economy (SCARE) |

| Nanomaterials / Low Dimensional Materials | Innovative Centre for Flexible Devices (iFlex) Mission

Max Planck-NTU Joint Lab for Artificial Senses Nanyang Environment & Water Research Institute (NEWRI) |

| Defence / Functional / Composite Materials | Emerging Nanoscience Research Institute (EnRI) Temasek Lab@NTU |

Contact Us to Explore Potential Collaborations or Facility Usage

Dr. Lee Mun Wai

Strategic Lead, Innovation Ecosystem Development (Research & Enterprise)

Email: [email protected]