About MS3015: Industrial Design (3AUs)

Industrial Design (MS3015) is a capstone core module taken by all third year MSE students. In this course, students will work in teams of 5 or 6 to tackle real-world, complex problems provided by industries. Students will learn to apply Design Thinking in their design processes and see through the entire conceptualization-to-production process during their 13 weeks in the course. As constant industrial involvement is central to authentic learning, each student team will be guided by a MSE faculty and their industrial mentor throughout the course to ideate, prototype and evaluate solutions.

By the end of the course, students will be able to:

- design a systematic plan based on sound design thinking processes to solve an identified problem

- work together as a team

- identify and apply engineering tools to solve identified problem

- present and market their work to an audience and a panel of judges

Call for industry partners

We are looking for companies to provide projects for MS3015. Problem statements can be from any industrial sector, preferably related to engineering/materials science.

- Participate as project mentors

Roles of mentors are:

● Attend weekly meetings with the student team(s)

● Conduct mid-term and final assessments - Provide materials/equipment access/training to the student teams (where applicable to their projects)

- Give a 1-hour seminar to all MS3015 students (schedule to be arranged at your convenience)

Dr. Eileen Fong

School of Materials Science and Engineering

50 Nanyang Avenue N4.1-02-09

Singapore 639798

Tel: 65138139

Email: [email protected]

Find out more about how industries can partner with MSE in education and research in this e-brochure.

MS3015 Projects

We are currently working with industry partners from many sectors, including

- Bralco Advanced Materials

- Cuprina

- Halliburton

- Hyperganic Pte Ltd

- OMS Oilfield Services

- PPG Coatings

- Se-cure Waste Management

- Vestfort Industries

Examples of past projects

Visit to OMS to understand more about company processes

Weekly discussions with industrial mentor from OMS

Final simulation produced by student team: Static Load Simulation using Solidworks

"Final wrap up for MS3015 pilot module! Was a good experience and ended with some nice egg tarts and food. Thank you Dr Eileen for all the support you have given us along the way! Group 1 & 2 love you!!!"

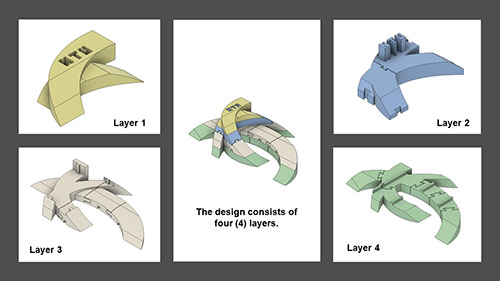

Technical Drawing

Building the Puzzle

"and… That’s a wrap for our MS3015 journey. Thank you, Dr. Eileen, and Mr. Istar for your guidance throughout this project."

"After 12 weeks of anxious, non-stop intensive discussions, lab work, troubleshooting, and optimizations, we finally wrapped up and presented our industrial project this morning. It has been a fantastic experience to work with Kirill, Michael, Aishwarya, Chen Yee, and Rachael as a team. My deep and sincere gratitude to our academic supervisor, Aravind Dasari, and mentors (Swaroop Narayanan, Ph.D., Sandeep Thatathil, Jonathan Siow, and Dean Seah), for their guidance and helps throughout the entire project. A special thanks to Chad Glaesman from Halliburton for lending us a helping hand in processing the materials. Our project would not be possible without the help from Halliburton. Lastly, I would like to thank Eileen Fong for giving us an opportunity to work closely with Halliburton."

Industrial Seminars

Mr Wu Linhan shared how their algorithms can rapidly produce material designs for testing in Hyperganic. Mr Wu Linhan shared how their algorithms can rapidly produce material designs for testing in Hyperganic. |

|

Mr Edwin Sia is the Strategy & Business Development Director (ASEAN) of Corning International. He was invited to spend the afternoon with the class to coach them on how to effectively present technical ideas. Mr Edwin Sia is the Strategy & Business Development Director (ASEAN) of Corning International. He was invited to spend the afternoon with the class to coach them on how to effectively present technical ideas. |

CEO of OMS Oilfield Services, Mr How Meng Hock shared with the students on his valuable insights on problem solving.

CEO of OMS Oilfield Services, Mr How Meng Hock shared with the students on his valuable insights on problem solving.