Adaptive Elastomeric Microwell Platform for Live Cell Encapsulation

Synopsis

An adaptive elastomeric microwell platform for live cell encapsulation. With tunable dimensions, it supports samples from single cells to organoids, enabling secure growth, high throughput, and gentle retrieval. It offers laboratories and manufacturers a cost-efficient, customisable solution for advancing cell research, diagnostics, and therapies.

Opportunity

Encapsulation of live cells involves enclosing them within a semi-permeable barrier that protects against immune attack and mechanical stress while allowing the exchange of nutrients and signalling molecules. This approach is widely used in biomedical research, diagnostics, and cell therapy manufacturing. Conventional methods typically suspend cells in polymer solutions that are cross-linked into beads or gels, sometimes preceded by microwell aggregation. While established, these approaches often suffer from limited adaptability, inconsistent sample sizes, and labour-intensive retrieval processes.

This technology introduces an adaptive elastomeric microwell platform that enables adjustable dimensions and high-throughput encapsulation of biological samples. It can accommodate a wide range of sample sizes, from single cells to complex multicellular aggregates such as tumour spheroids and organoids. The platform supports physiologically relevant growth and proliferation, and importantly, allows encapsulated samples to be released intact without enzymatic or harsh mechanical disruption.

By combining flexibility, secure encapsulation, and gentle retrieval, this solution addresses a clear market need for customisable and cost-efficient live cell handling. It holds strong potential for research institutions and Institutes of Higher Learning engaged in cell biology, organoid research, and advanced drug screening; for pharmaceutical and biotechnology companies seeking scalable, contamination-free sample preparation for R&D and clinical use; and for clinical laboratories and hospitals requiring standardised, zero-loss handling of rare or patient-derived samples. In addition, laboratory equipment and consumables manufacturers may benefit from integrating this platform into existing product lines or automation systems, extending its impact across the broader life sciences and healthcare ecosystem.

Technology

- Mechanically tunable microwell size via controlled stretching, allowing both capture and release of samples.

- Zero chemical additives required for encapsulation, ensuring compatibility with sensitive assays and cell systems.

- Size-based classification capability to separate samples by dimension prior to downstream processing.

- 3D confinement similar in scale to the captured sample, promoting physiologically relevant growth patterns such as organoid or spheroid formation.

- High-throughput array format, supporting simultaneous processing of multiple samples.

- Supports growth-based trapping, where small aggregates proliferate into encapsulated multicellular structures.

- Reusable and compatible with standard laboratory handling equipment (e.g. pipettes).

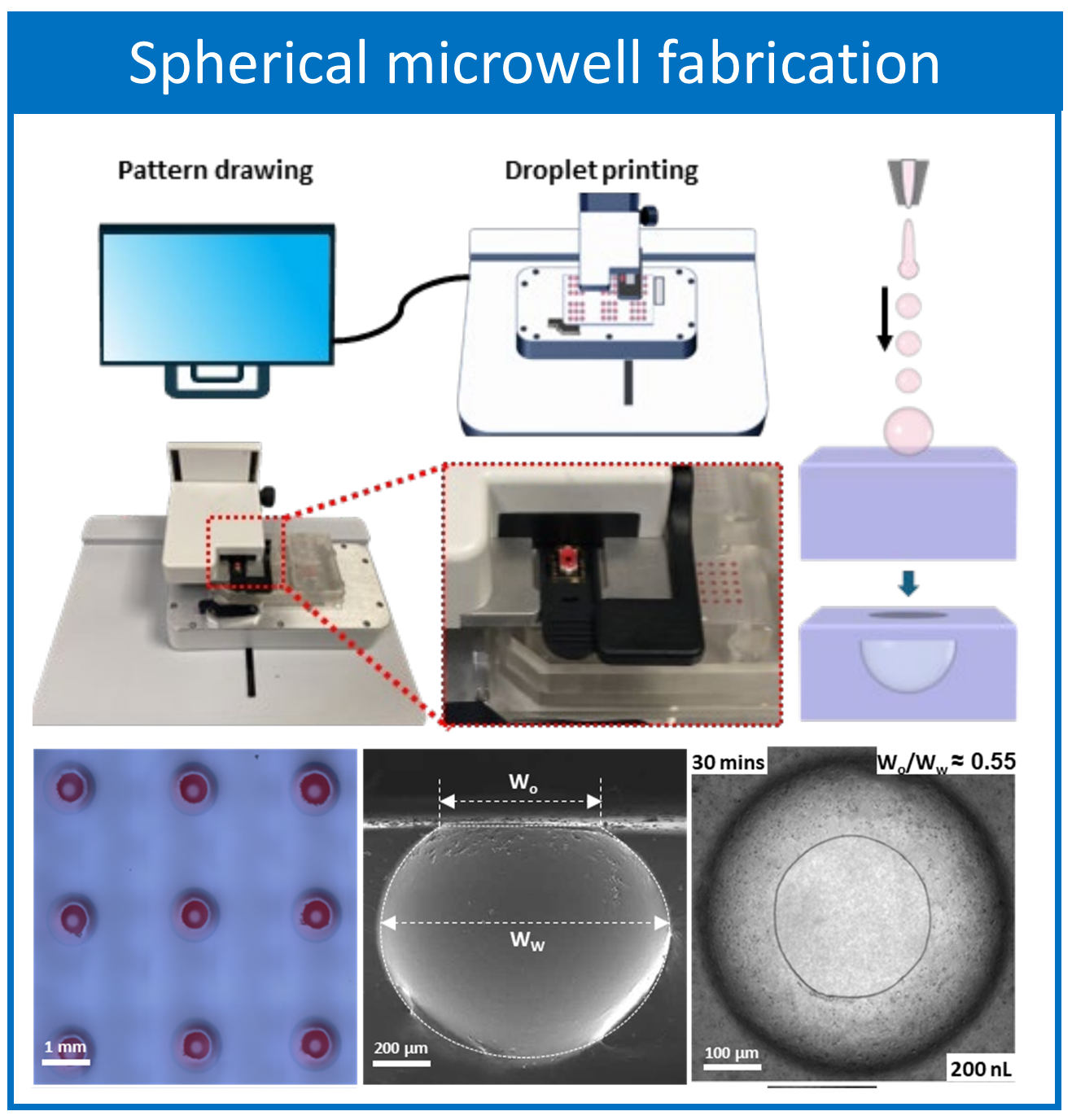

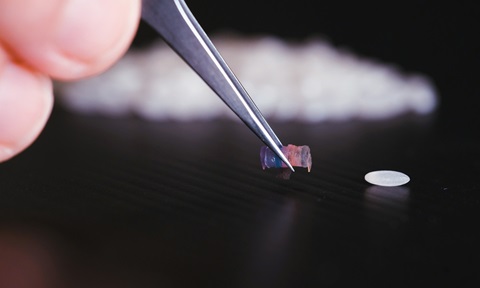

Figure 1: Schematic and associated images of the fabrication of spherical microwell.

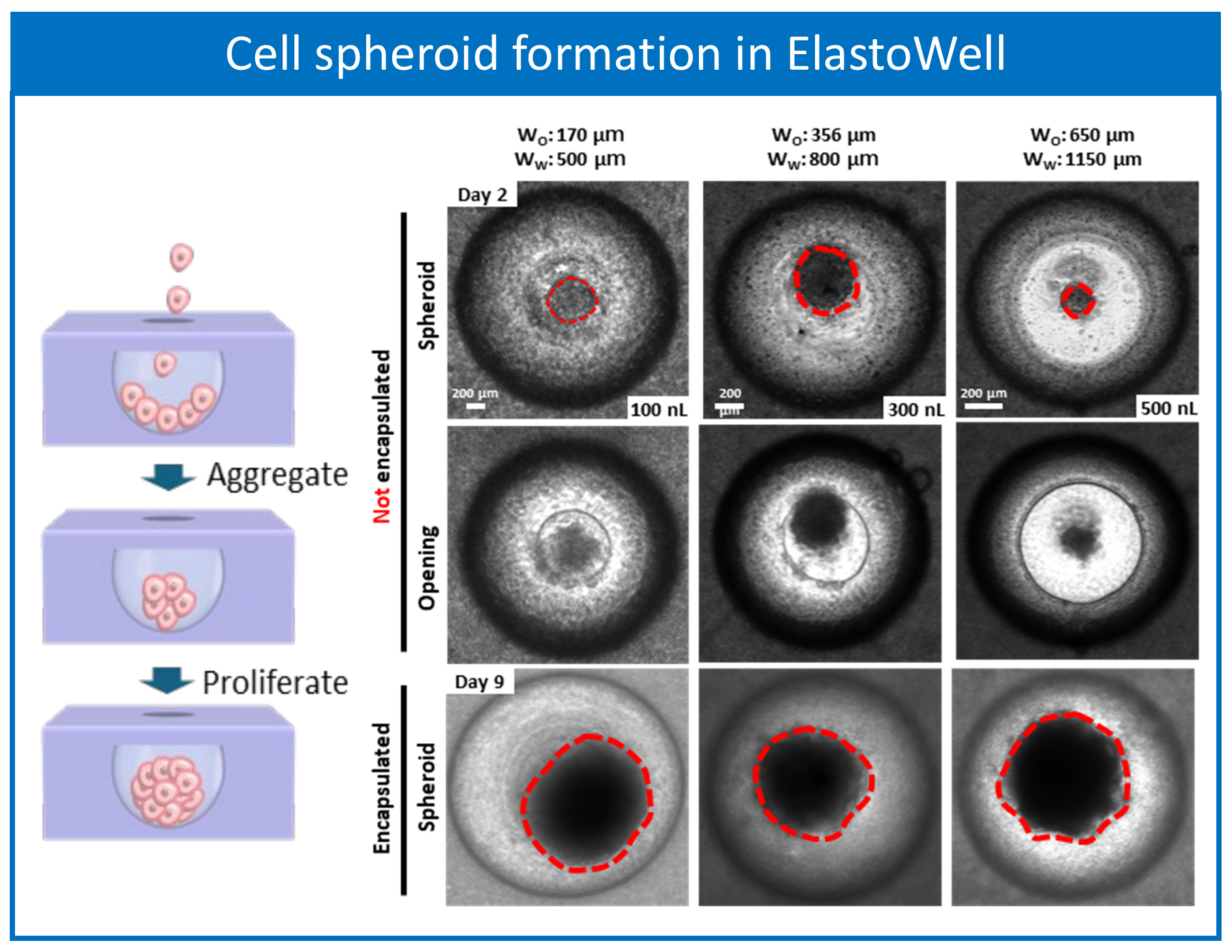

Figure 1: Schematic and associated images of the fabrication of spherical microwell. Figure 2: Images showing cell spheroid formation in ElastoWell.

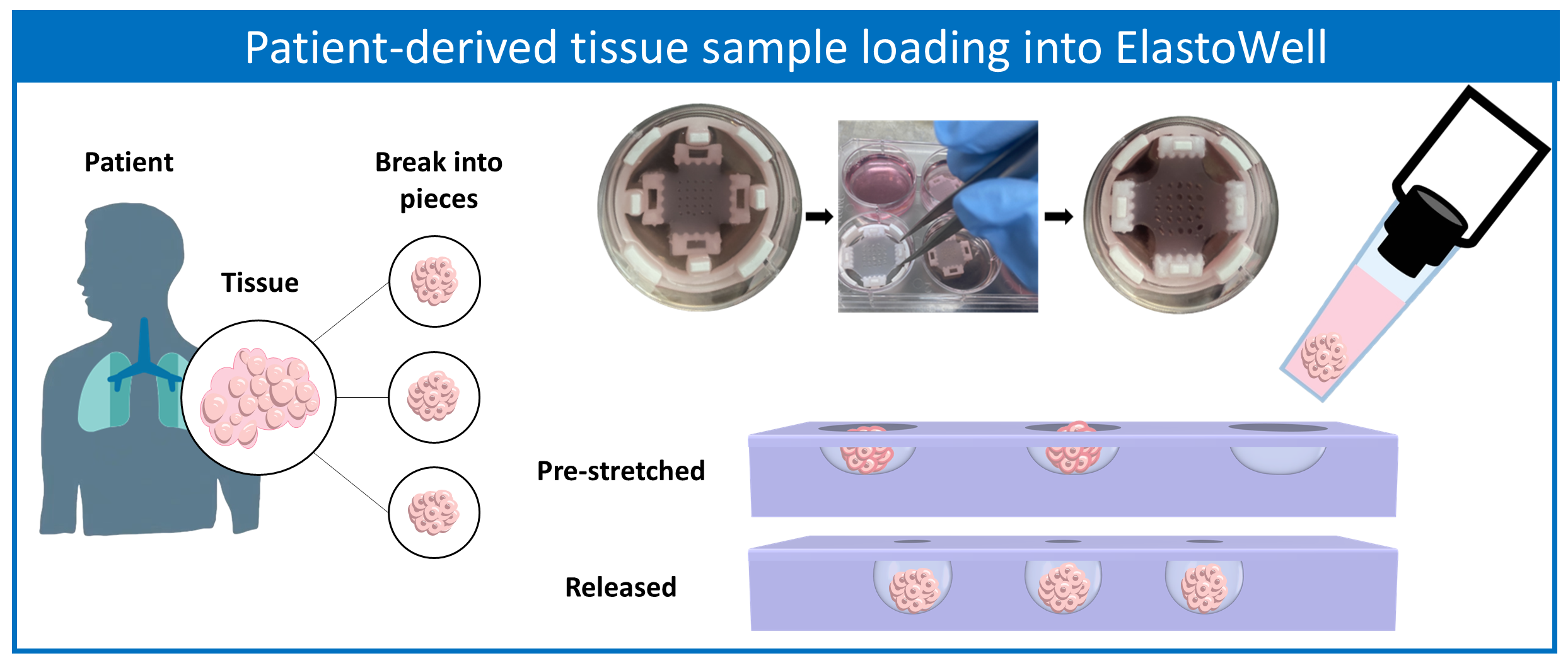

Figure 2: Images showing cell spheroid formation in ElastoWell. Figure 3: Schematic showing how patient-derived tissue samples can be loaded into ElastoWell.

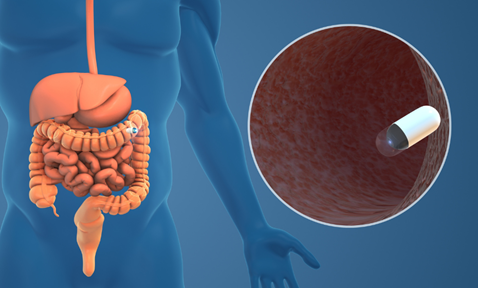

Figure 3: Schematic showing how patient-derived tissue samples can be loaded into ElastoWell.

Applications & Advantages

Applications:

This technology has broad applicability across pharmaceuticals, biotechnology, life sciences, clinical diagnostics, and research tool manufacturing. It is particularly valuable for organisations engaged in live cell handling, organoid development, precision medicine, and advanced drug screening.

Key applications include high-throughput drug uptake and penetration studies with controlled sample sizes; organoid and tumour spheroid culture for disease modelling and therapeutic testing; preservation and zero-loss handling of rare or patient-derived samples in both clinical and research workflows; and sample encapsulation for transport, enabling long-distance or cross-border delivery of live cells without cryopreservation. The platform also supports size-based sorting of cell aggregates to improve assay reproducibility, as well as personalised medicine workflows such as patient-specific testing and screening.

Potential marketable products include consumable elastomeric microwell plates with adjustable well sizes, modular encapsulation (release units compatible with automated liquid handling systems), and fully integrated sample preparation platforms for laboratory and clinical environments. These product formats allow seamless adoption into existing workflows, delivering scalable, contamination-free, and loss-preventing solutions for modern cell-based research and therapeutic applications.

Advantages:

This technology is the first elastomeric microwell platform to enable fully reversible sample encapsulation and release without chemical additives. Its purely mechanical operation integrates seamlessly into existing laboratory workflows, eliminating chemical exposure, reducing processing steps, and minimizing contamination risks.

Unlike conventional methods, the platform ensures zero sample loss, making it especially valuable for rare or low-quantity samples. It uniquely combines adjustable well dimensions, high-throughput capacity, and individual sample release within a single system.

By providing a three-dimensional microenvironment that reflects the natural scale of biological samples, the platform supports physiologically relevant growth of advanced models such as organoids and tumor spheroids. It delivers a versatile, contamination-free, and loss-preventing solution tailored to the needs of modern cell biology, pharmaceutical research, and clinical applications.

-and-dr-dorrain-low-from-ntu-singapore's-lkcmedicine.tmb-listing.jpg?Culture=en&sfvrsn=b389b500_1)

.tmb-listing.jpg?Culture=en&sfvrsn=82921582_1)

.tmb-listing.jpg?Culture=en&sfvrsn=ba129532_1)