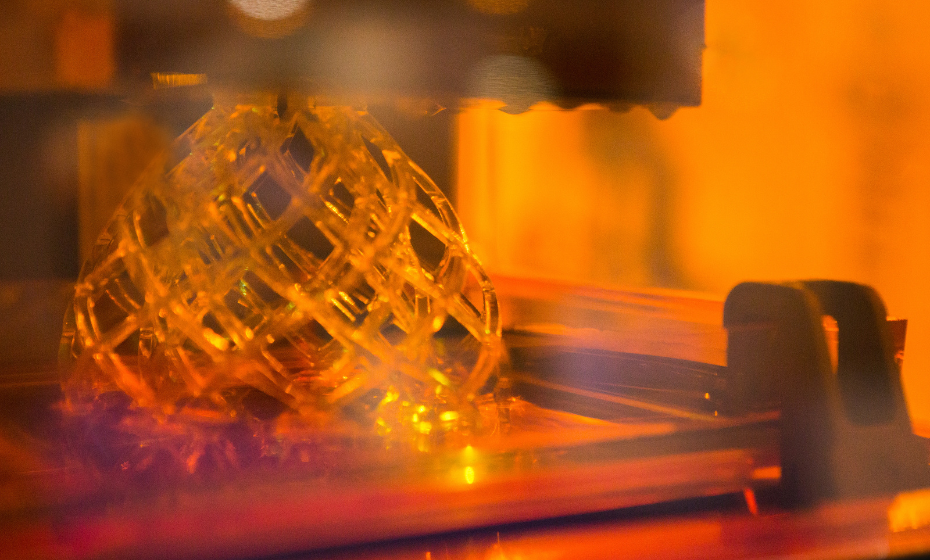

Stereolithography 3D-Printing Transparent Spinel Ceramics

Synopsis

This technology enables high-transparency 3D-printed spinel ceramics with complex geometries, combining proprietary ceramic paste, 3D printing, and specialised heat treatment. The resulting ceramics offer excellent mechanical strength, optical clarity, and design flexibility, providing a sustainable and efficient alternative to conventional materials such as YAG, sapphire, and 3D-printed silica glass.

Opportunity

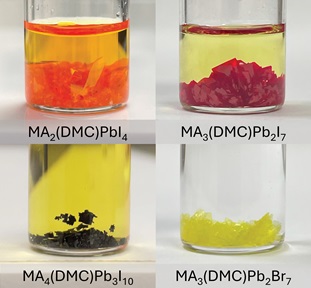

There is a growing global demand for complex-shaped transparent ceramics such as spinel in specialised lenses, optoelectronics, electronics, semiconductor, and biomedical applications. However, large-scale commercial production of ceramic parts with high transparency and complex geometries has not yet been fully established. At present, most transparent ceramics are commercially fabricated in simple geometries using conventional methods such as injection moulding or hot-pressing. 3D-printing techniques such as direct ink-writing, digital light processing, and stereolithography have enabled the fabrication of ceramic parts of greater complexity, but the optical transparency of such ceramic parts remains limited.

This technology is among the first to provide high-transparency 3D-printed spinel ceramics with highly complex designs. It integrates proprietary spinel ceramic paste, a 3D printing process, and a specialised heat treatment process. The resulting 3D-printed ceramics possess a high relative density, exceptional mechanical strength, good optical transparency, and wide design flexibility. Together, these advantages position the material as a strong alternative to current options such as 3D-printed silica glass, yttrium aluminium garnet (YAG), and sapphire. Moreover, compared with conventional manufacturing methods, 3D-printed spinel ceramics significantly reduce material waste while shortening the prototyping-to-production timeline. This appeals to both industrial applications and sustainability.

This technology supports a wide range of design complexities, resolutions, and application needs. The technology owner is currently seeking further industry collaborators who are interested in exploring and pushing the boundaries of 3D-printed transparent ceramics. They are able to offer flexible co-development modes for specific use cases for partners with or without existing in-house 3D printing capabilities.

Technology

This technology consists of the entire production process for producing 3D-printed transparent spinel ceramics. This includes:

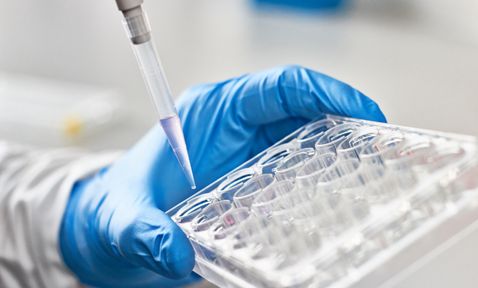

- Expertise and know-how in 3D print paste formulation

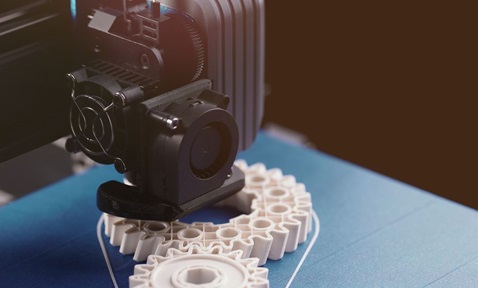

- 3D print process parameters

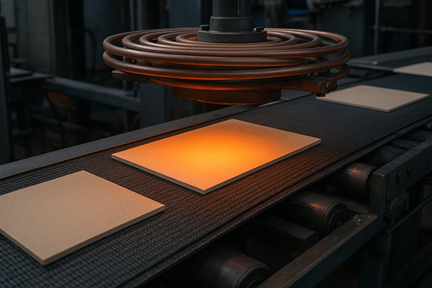

- Post printing heat treatment process

Through our production process and expertise, the 3D-printed spinel products would have the following properties:

- >80% Transmittance at λ = 500-700 nm

- Hardness = 11.0 to 13.5 GPa

- Printing resolution = ~200 µm

- Product size = 4cm^2 to 35cm^2

- High complexity design

Applications & Advantages

Some potential applications include (but are not limited to):

- Semiconductor industry, e.g. equipment requiring transparency in harsh plasma or high-temperature environments

- Defence industry, e.g. shrapnel-resistant transparent surfaces

- Medical industry, e.g. surgical jigs and guides

- Dental industry, e.g. transparent or translucent dental brackets

- Optical industry, e.g. specialised lenses

- Other industries: applications requiring transparent & strong parts with intricate designs, applications requiring photocatalyst support, fashion

.tmb-listing.jpg?Culture=en&sfvrsn=40b426f_1)

.tmb-listing.jpg?Culture=en&sfvrsn=29c7e020_1)

.tmb-listing.jpg?Culture=en&sfvrsn=3b74ec1c_1)