Centre of Advanced Material

The Advanced Material Team in TL@NTU have extensive material development capabilities and system integration expertise over decades of experience. Our material synthesis repertoire includes (but is not limited to):

- Micro/nanomaterials

- High performance ceramics and composites

- Functional polymer and composite systems

- Nano Carbon and Boron Nitride (C and BN) based materials for a variety of applications

Find more information about the different materials below:

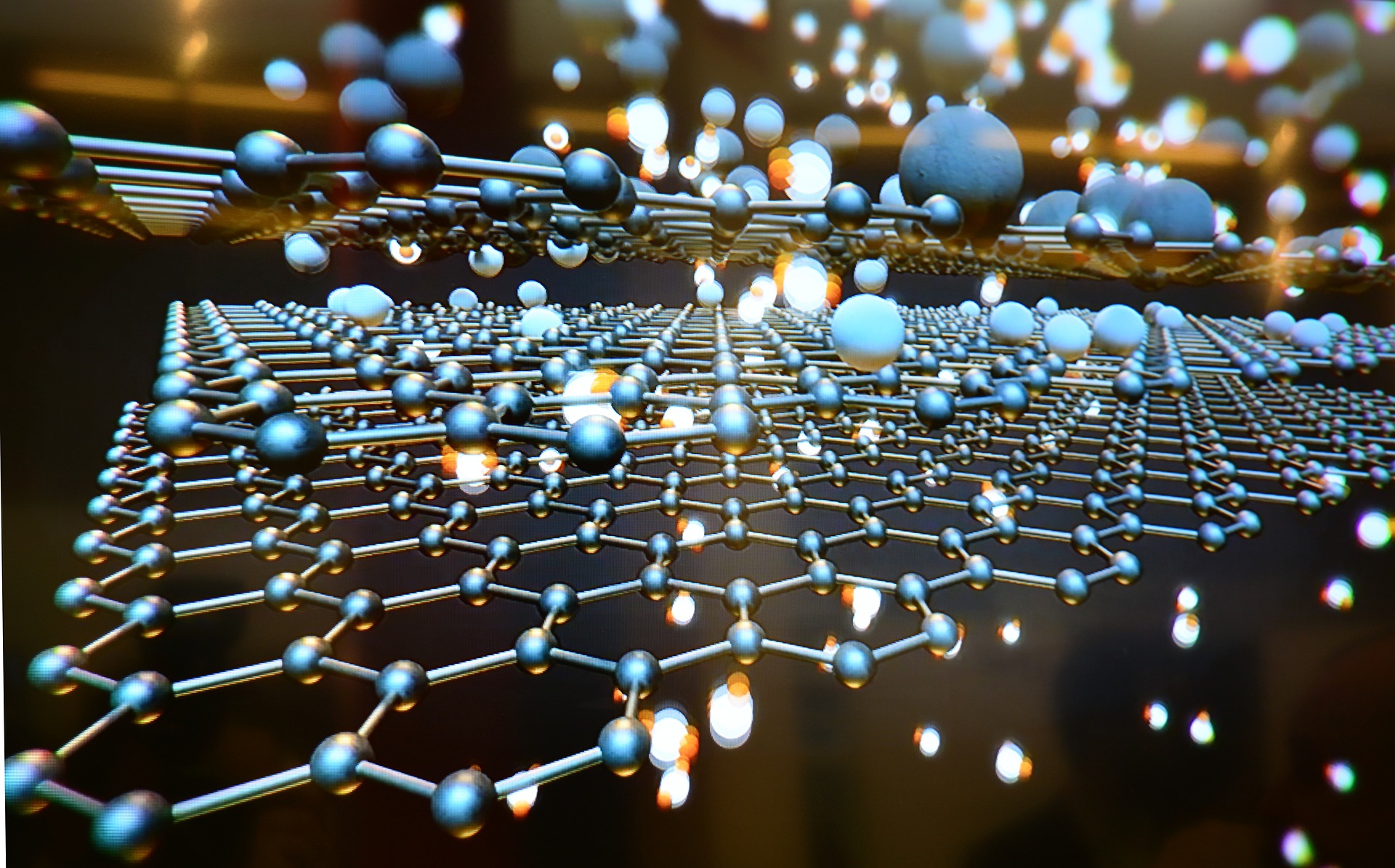

Nano Carbon and Boron Nitride (C and BN) based materials

Quixotically, BN and C can be thought of as ideal Yin-Yang counterparts, same in some ways which allows for ease of intermixing yet wholly different in others to enable tuning of properties. Using this aspect of the materials, the team purposefully configure the nano variants of BN and C to elicit explicit properties which can be exploited for targeted applications. Here the team can synthesize all variants of the materials from 0D quantum dots to 1D nanotubes to 2D surfaces to 3D foams and even diamond films. Our application domain ranges from thermal regulation and control, space materials, re-generative medicine, artificial skin for robotics, thermal acoustics to emerging materials for defense applications. Our in house capability stretches the entire range from design of materials to optical, thermal and electrical characterization to integration testing and performance benchmarking.

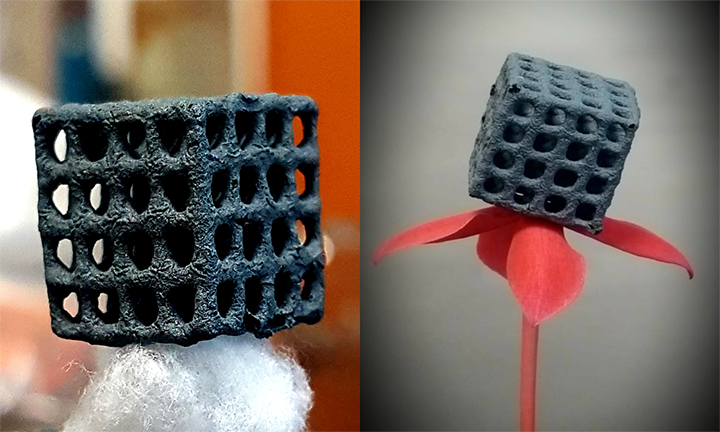

Advanced Ceramics Group

Led By Prof Gan Chee Lip/ Dr Du Zehui

The Advanced Ceramics Group in TL has over ten years’ research experience in developing various high-performance ceramics, and ceramic or metal matrix composites. Our research capabilities are established from a solid foundation of the processing sciences to fabricate various ceramic structures, such as particles, nanofibers, foams and bulk ceramics. A comprehensive range of processing and testing equipment has been established for the research, including planetary ball mill, planetary centrifugal mixer, debinding furnace, pressureless and pressurized sintering furnace, DIL, in-situ nanoindentation, FIB/FESEM/EBSD/EDX, AFM, X-ray micro-CT, etc. Besides developing new ceramic structures, we have also devoted great effort to improve their mechanical properties and functionality for various applications in protection, structural support, actuation, optical and electromagnetic manipulation. The team has published over 50 journal papers and filed 7 patents and technology know-hows, with some of the publications highlighted in Sciencedaily and Ceramics.org. Our current research focus includes the following topics:

- 3D printing of transparent ceramics and rational design of the structures for optical application, LED lighting and photocatalyst support;

- SLA 3D printing of SiC and Si3N4 ceramics: paste optimization and structural applications;

- Ultrafast sintering of ceramics through UHS and flash sintering mechanism;

- Development of shape memory ceramics and exploration on their applications in composites;

- Development of non-lead dielectric ceramics with dense or porous topology.

Selected publications:

- Haomin Wang, Li Ying Liu, Pengcheng Ye, Zhangyi Huang, Andrew Yun Ru Ng, Zehui Du,* Zhili Dong, Dingyuan Tang, Chee Lip Gan*, 3D Printing of Transparent Spinel Ceramics with Transmittance Approaching the Theoretical Limit, Adv. Mater. 2007072(2021)

- Xiu Yun Yap, Ian Seetoh, Wei Liang Goh, Pengcheng Ye, Yida Zhao, Zehui Du*, Chang Quan Lai*, Chee Lip Gan*, Mechanical properties and failure behaviour of architected alumina microlattices fabricated by stereolithography 3D printing, Int. J. Mech. Sci., 196,106285(2021)

- Zehui Du, Xinran Zhou, Pengcheng Ye, Xiaomei Zeng, Chee Lip Gan, Shape-Memory Actuation in Aligned Zirconia Nanofibers for Artificial Muscle Applications at Elevated Temperatures, ACS Appl.Nano Mater., 3(3), 2156-2166 (2020)

- Zehui Du, Xiao Mei Zeng, Qing Liu, Christopher A. Schuh, Chee Lip Gan. Superelasticity in shape memory ceramic particles at micro scales, Acta Mater., 123, 255-263(2017)

- Alan Lai, Zehui Du, Chee Lip Gan, Christopher A. Schuh, “Shape Memory and Superelastic Ceramics at Small Scales”, Science,341, 1505-08(2013)

Polymers & Composites

Led by Prof Hu Xiao

The expertise in polymer science and engineering as well as chemistry and nanotechnology enabled us to create engineered polymers, composites and hybrid materials for specific applications. Our design principle is based on in-depth understanding of the mechanisms and structural origin of the unique mechanical, thermal, electronic, photonic and dielectric properties of these materials. Bio-inspired approach is credited for the development of tough and highly processible preceramic hybrid resins, and functional nano-fibers mimicking the infrared (IR) reflectance of vegetation foliage. Another innovation is the specifically designed “molecular charge traps” to substantially enhance the breakdown strength of functional dielectric polymers. Our advanced resin systems, including preceramic hybrid resins, were designed for high performance light-weighting, thermal management, electronic packaging, signature reduction and more. A recent initiative is to address the key challenges in additive manufacturing via molecular design.

Micro-/ Nano- materials

Led by Dr Lai Changquan

The Advanced Materials Design & Synthesis (AMDS) Group aims to develop high performance materials through innovative research in design and manufacturing processes. Basic and applied research in functional design is carried out through analytical means, finite element simulations and machine learning techniques. The primary choice of fabrication method is additive manufacturing, which we also research on actively, by developing compatible novel materials and optimizing process parameters. Special focus is currently given to micro-/ nano- materials, auxetic structures and interpenetrating phase composites.