Solder Alternative Technology for Fine Pitch & Environmental-Friendly IC Packaging

Investigators: Prof Subodh Mhaisalkar, A/P Wong Chee Cheong, Prof Chen Zhong, Prof Freddy Boey

Flip chip polymer interconnects are well positioned to respond to the relentless need for speed, miniaturization, reliability, and environmentally-friendliness demanded by the next generation of micro and nano electronic devices.

Instead of using lead-based solder materials, nanostructured interconnect systems based on anisotropic conductive adhesives (ACA), non-conductive adhesives (NCA), and isotropic conductive adhesives (ICA) offer an excellent avenue to achieve reliable interconnects which could perhaps be scaled down to pitches finer than 20 microns.

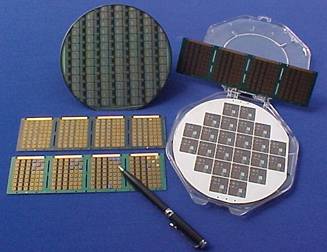

In this active collaboration with the Institute of Microelectronics (IME), the project aims to develop guidelines for implementation of adhesive flip chip interconnect technology for ultra-fine pitch IC Packaging, in terms of material properties, assembly process and mechanical design. It is also the objective of the project to assess feasibility of utilizing modified adhesive flip chip technology for ultra-fine pitch (<20um) interconnects with the projected application in assembly/packaging of nano-technology wafers. This involves the development of insulated nano-metallic particles and new test methods for characterizing the performance of adhesives. This project should eventually lead to a technology breakthrough, revealing the real potential of the solder alternatives.

The project team is near to the completion of assembling test vehicles with various NCA & ACA materials. Their thermo-mechanical, moisture & visco-elastic properties are also being characterized for the subsequent correlation analysis. The team are also working on modified chemistry & process for ultra-fine pitch wafer bumping & ACA/NCA interconnects, while exploring new hypothesis of failure mechanisms.

SEM and Atomic Force Micrographs showing good morphology of SixNy