CEE Research Conversations: A Hybrid AI Approach to Smarter Hull Maintenance and Energy Efficiency

Summary

- Hull fouling, the accumulation of marine organisms on a ship's hull, increases hydrodynamic resistance, leading to higher fuel consumption and greenhouse gas emissions. While the resulting energy penalties can be significant, current evaluation methodologies are often time-consuming and costly to predict accurately.

- To address this, Kim Youngrong, an Assistant Professor at NTU’s School of Civil and Environmental Engineering, developed a prediction framework that combines physics-based models with AI.

- The data-driven tool can quantify energy penalties caused by specific hull fouling conditions, enabling operators to make decisions for proactive maintenance planning and operational optimisation.

Preventing hull fouling is a clear and cost-effective strategy for maritime decarbonisation. While the shipping industry adopts expensive solutions such as alternative fuels, simple fouling management can reduce greenhouse gas emissions by an estimated 10%.

However, operators lack practical tools to quantify the loss in real time. Existing methods such as Computational Fluid Dynamics (CFD) are unsuitable for instant evaluations, while diver inspections only provide qualitative results.

Recognising these limitations, Assistant Professor Kim Youngrong was motivated to develop a tool that translates ambiguous hull conditions into concrete economic losses, assisting operators to make rational and eco-friendly decisions instantly.

Employing AI in Shipping

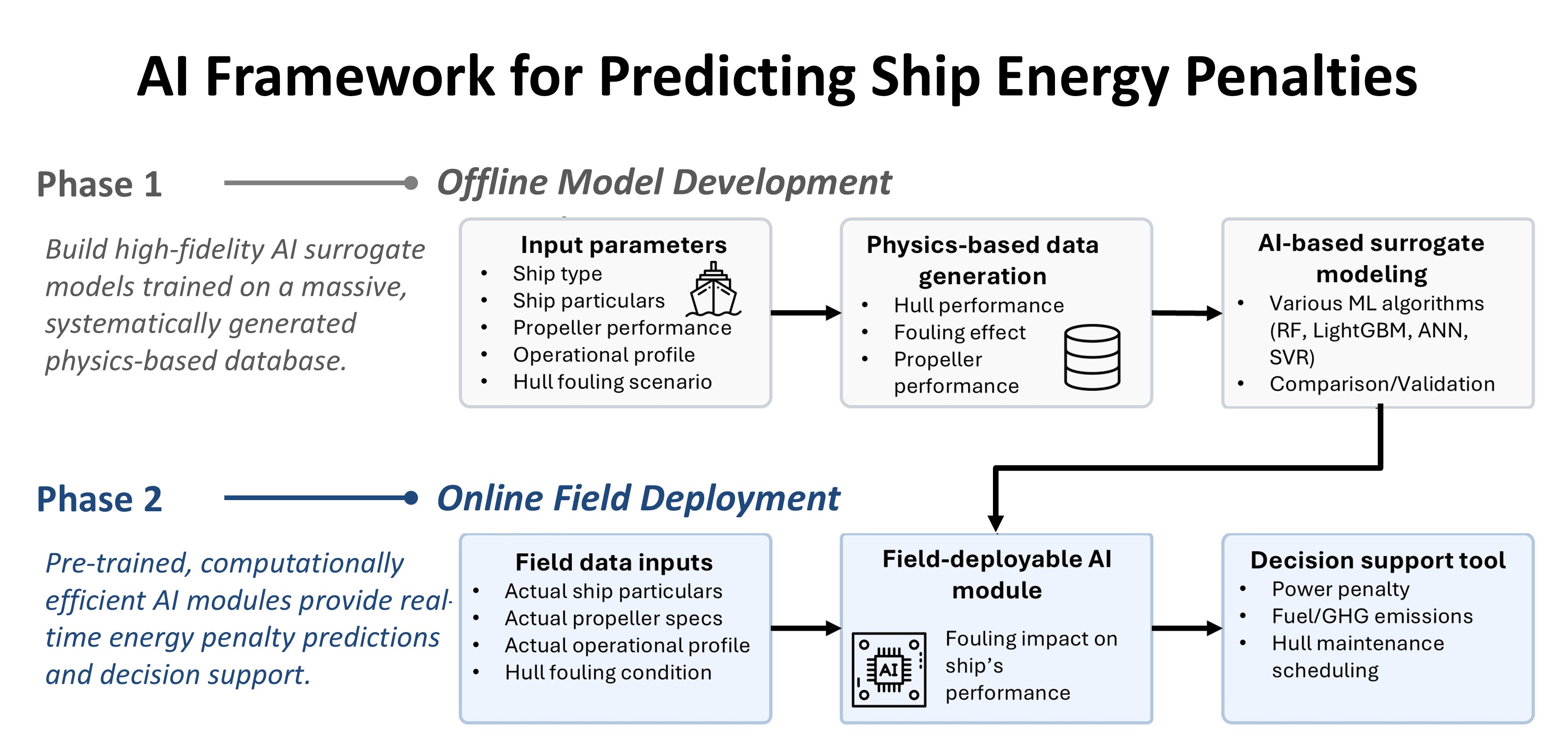

The research introduces an AI-based prediction framework developed in two phases:

Phases 1 and 2 of Developing the AI Framework

Offline Phase

Complex physics models were used to perform the heavy lifting in generating over 30 million scenarios based on 53,000 ships and this massive dataset was used to train the AI models.

Online Phase

In this phase, the pre-trained, lightweight AI was deployed to the field. It no longer needs to solve complex equations but simply recalls the patterns it learned to deliver instant predictions on tablets or computers. This allows the tool to be made accessible to ship operators, inspectors, cleaning companies, or port authorities.

Adopting a Hybrid Approach

Relying purely on AI is not practical as these data-driven models may violate physical laws or generate inaccurate outcomes.

To overcome this, the overall physical workflow was retained while replacing the computationally intensive bottlenecks with AI surrogates, specifically those related to hull and fouling resistance calculations. This hybrid approach provides the reliability of physics and the practicality that can be applied in the field.

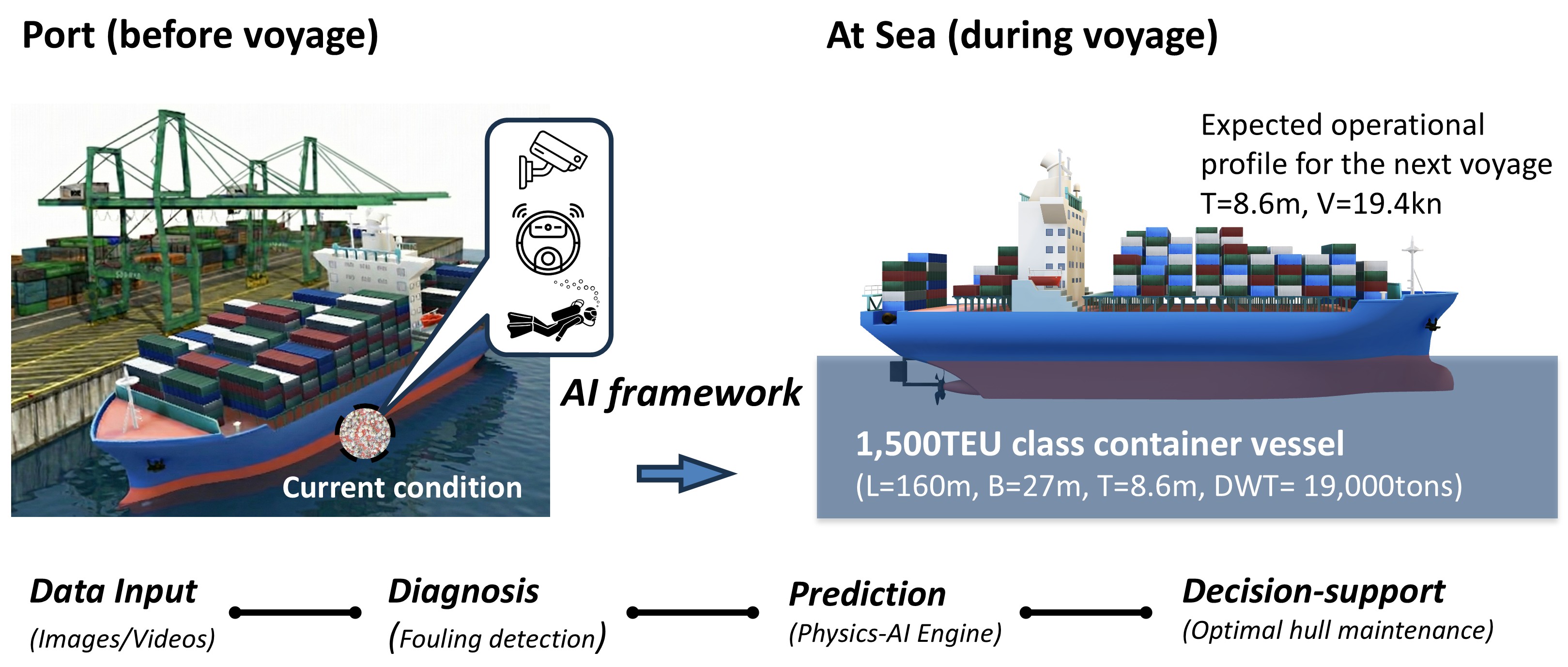

A Breakdown of the AI Framework

The resulting framework enables optimal field decision-making by balancing fuel loss costs from fouling against cleaning expenses, while also accounting for broader socio-environmental impacts.

Taking AI to the Next Level

Looking ahead, Assistant Professor Kim plans to integrate vision AI to automatically detect fouling conditions from underwater images or videos captured by remotely operated underwater vehicles (ROVs). His long-term vision is to create an optimised condition-based maintenance system covering the entire pipeline from image capture to cost analysis.