Geopolymer concrete printing

Technology Overview

About two decades after its first proof-of-concept, 3D concrete printing is on the threshold to become more matured. It provides new opportunities such as higher degree of architectural freedom, lower costs due to a lack of scaffold, less labour intensive manpower and less material required. To achieve these, the print processes need to be more robust. Therefore, there is increasing demand to develop new generation of thixotropic material that can retain its shape after extrusion.

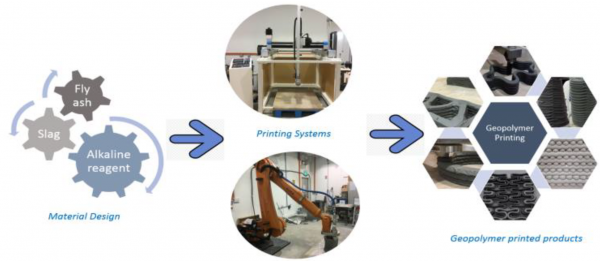

The 3D printable geopolymer cement is a novel technology developed that uses industry by-products such as fly ash, slag, silica fume etc. The motivation behind using different by-products rather than Ordinary Portland Cement is to provide sustainable, faster and more economical urban infrastructure. It is proven that this technology is able to meet the strength requirements for various non-structural applications, reduces material wastages and construction time.

Technology Features & Specifications

The technology comprises of the following processes and steps:

- Material development: using industrial by-products and transform them to a suitable binder using advanced geopolymerization technology

- Mixing and placing: a continuous mixing system that delivers wet mix instantly

- Dispensing unit: using both a gantry or robotic system to 3D print the structure, allowing for near net shape end produc

Potential Applications

Potential applications for this technology, but not limited to, is as follows:

- Pre-cast industries for printing of mould/form work instead of carving complex shapes out of wood or metal plates

- For low cost housing components (Non-structural)

- For building planners and architects, where freeform design can be achieved easily directly from 3D computer model

- Modular construction

- Decorative stone artefacts

Market Trends and Opportunities

In 2017, the global geopolymer market was estimated at more than USD 3200 million and is set to grow to at a CAGR of about 37% over the next 5 years. Market segmentation according to end-user application revealed that in 2017, the buildings segment dominated the global geopolymer market with about a 20% market share.

Customer Benefits

- Low cost housing using locally available by-products together with 3D printing technology

- Architects can print their freeform designs by taking the benefits of concrete printing

- A faster, safer and sustainable manufacturing process