Recycling of Silicon Solar Panels

Electricity generation from photovoltaics (PV) is expected to be one of the key technologies of the 21st century. With a positive impact on the environment as well as nearly zero carbon emission during operation, PV technology is expected to grow rapidly in the near future. However, as all the technologies will eventually reach end-of-life stage, proper management tools are indispensable for PV modules. With the current state-of-the-art technologies, the expected lifespan of a PV module is around 30 years. With rapid growth of PV industries, the number of end-of-life PV modules will eventually accumulate proportionately as PV waste. Global PV is estimated to reach 4%-14% of the new installation by 2030, and climbing to over 80% in 2050 (International Renewable Energy Agency (IRENA)). Given the rapid surge in PV deployment amongst developed countries and the huge PV market in Asian giants, the PV waste generation is expected to grow by more than 10% of the global e-waste generation by 2050. Among the various PV technologies, Si-wafer based PV technology accounts for more than 90% of the total global production and will remain so in the future, resulting in massive crystalline Si PV waste generation. Additionally, recycling Si PV modules will reduce the carbon footprint. For example, recycling of 1 ton of Si PV panels will approximately save 800-1200 kgCO2eq global warming potential(GWP) as compared to PV panels manufactured from primary materials.

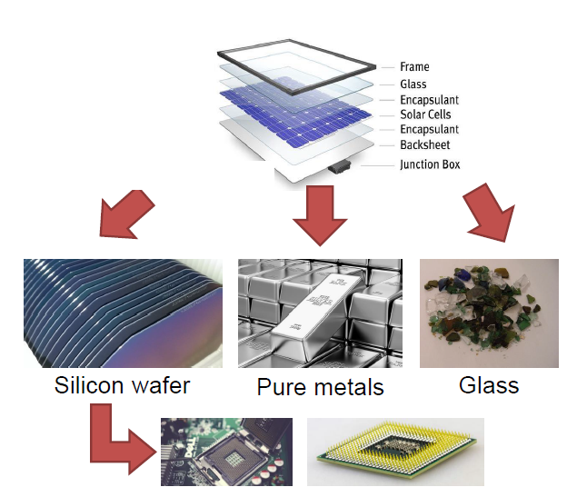

The current industrial process of recycling PV modules allows an ~80% recycling target to be met, mostly by recovering their metallic frame (aluminum) and glass, with the remaining flat active sandwich composite structures often being discarded and landfilled (France, EU).To achieve higher recovery yield and to extract better economic value, one must target the recycling of the PV module’s active sandwich structure. This will enable the recovery of In, Si, Ag, Ga in these structures from the solar cells. Unfortunately, clean and eco-friendly recycling technology is yet to be developed to process large quantities of waste PV modules at a reasonable cost to ensure that PV technology remains a clear ‘clean energy source’.

This is therefore the target of the project: To develop new approaches to recycle laminated solar panels by promoting safety, efficiency while closing the loop on basic materials. Such a process enables (i) the disassembly of flat sandwich composite structures of the PV modules; and (ii) the recovery of secondary raw materials from the multi-materials disassembled layers, such as Si, Ag, In, Ga and other metals.