Recycling and Recovery of Valuable metals from Printed Circuit Boards

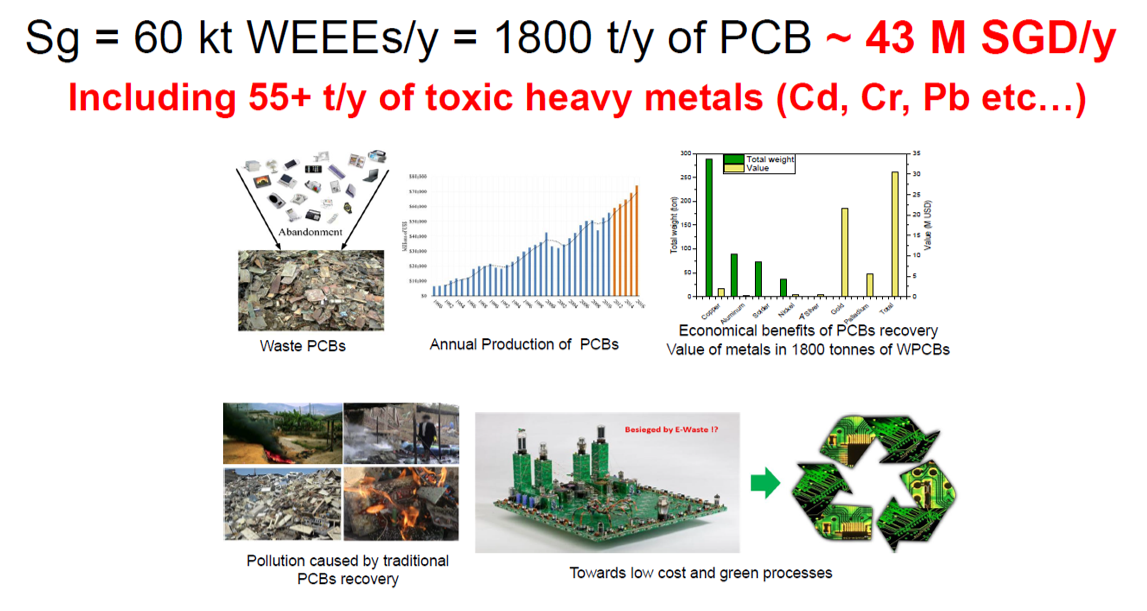

Nowadays, rapid economic growth, continuous technological innovation and the improvement of living standards have result in large amounts of waste electric and electronic equipment (WEEE). Hence, Singapore is the second-largest generator of e-waste in the region, second only to Hong Kong. Amongst all these WEEE, waste printed circuit boards (WPCBs) are considered as the most valuable components due to precious metals contained. In average worldwide, WPCBs represent about 8% by weight of WEEE collected from small appliances and 3% of the mass of global WEEE. The presence of precious metals at higher concentration in WPCBs than in typical metal mines, has driven the extraction of the precious metals from WPCBs into a profitable business sometime without proper pollution controls However, in average, PCBs contain 40% of metals, 30% of organics and 30% ceramics. Hence, beyond usual precious metals (Au, Pt, Pd, Ag), other critical metals (rare earth, In, Sb, Co, Si), heavy metals (Sn, Pb, Bi, In, Cd, Sb, Cr) or semi-conductors (Si, Ge, P) as well as organics and ceramics are present that must be adequately dealt with and if possible recovered/ recycled. The recovery of heavy metals would also prevent further water and soil contamination, which raises huge environmental concerns. Overall, separation and recovery of all these fractions beyond the recovery of precious metals is the current challenge because of their complex materials makeup. Proper technologies to recycle most materials from WPCBs without negative effects to the environment are urgent and essential.

In this project, (i) advanced sorting techniques is developed and applied for the initial segregation of WPCBs; (ii) improved separation process is investigated; (iii) new techniques is applied in the hydrometallurgy processes to enhance the recovery/ extraction efficiency. Finally, we evaluate the economic viability of these new environmentally friendly techniques in the Singaporean specific economic context in comparison with the current pyro/ hydrometallury processes. For the processes that are positively evaluated, demonstration with laboratory scale prototypes in order to favour further industrial collaborations and technology deployments is done.