Research Collaboration

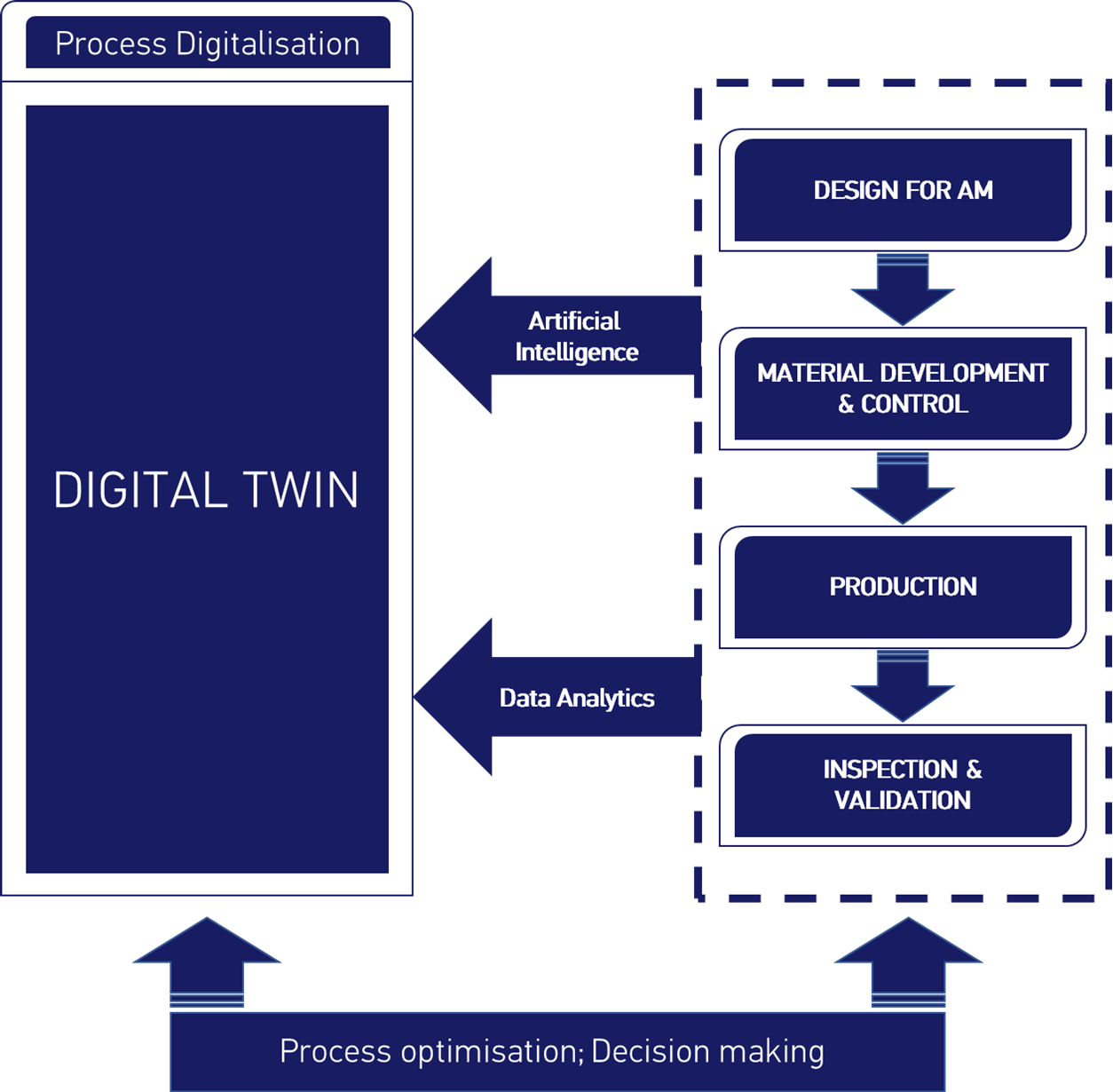

The Singapore Centre for 3D Printing (SC3DP) offers a full range of additive manufacturing services, from design and infrastructure to production and validation. With advanced technologies such as topology optimization, generative design, and bioinspired design, SC3DP creates optimized products using a variety of novel materials and printing processes, including hybrid printing, post-processing, and emerging technologies. Sustainability is a top priority for SC3DP, which offers material development and control services that combine artificial intelligence, big data, and other digital tools for process optimization, as well as non-destructive testing for AM parts. Backed by a team of experts and a state-of-the-art facility equipped with the latest equipment and technologies, SC3DP is committed to leading the way in sustainable additive manufacturing research and development.

•Material certification

Enquiries

Kickstart your additive manufacturing transformation journey with us