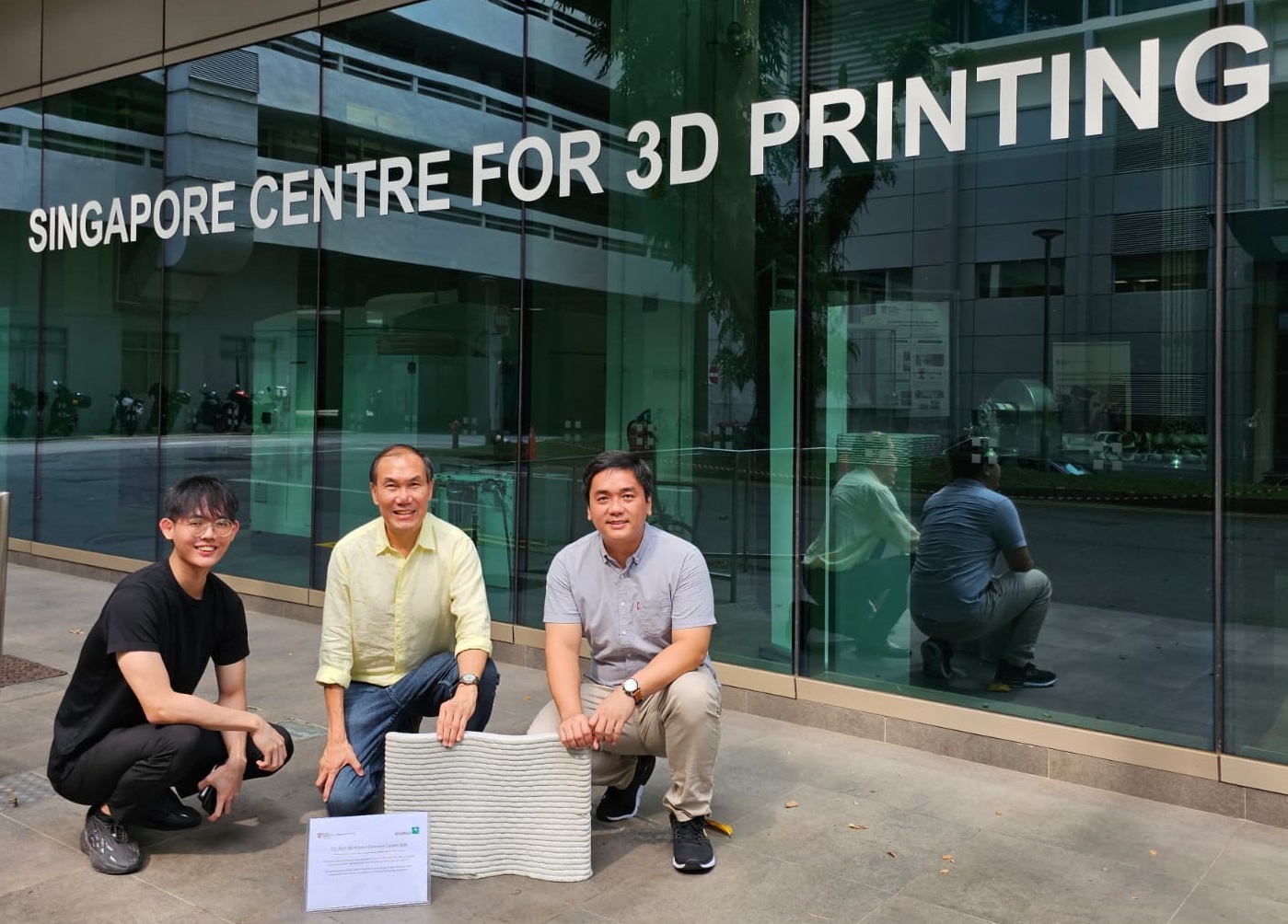

Collaboration with Saudi Aramco Technologies Company (SATC)

Nanyang Technological University, Singapore (NTU Singapore) and Saudi Aramco Technologies Company (SATC) signed an agreement on 28 August 2023 to foster collaborative research to explore the synergistic effects of coupling both 3DCP and CCS (carbon capture & sequestration) technologies, so as to facilitate the transition towards sustainable construction that satisfies a net-zero emission target. With increasing initiatives across the globe to achieve a net-zero emissions target by 2030, more effort needs to be made in order to successfully decarbonize the construction sector. Based on literature review, carbon curing with pressurized chambers has been suggested to provide a solution when it comes to reducing the carbon footprint of precast concrete. However, when considering its application on a larger scale, the utilization of confined chambers for carbon sequestration would relinquish numerous key advantages, such as scalability, cost-effectiveness, and operational feasibility. In order to eliminate the physical constraints of a chamber curing solution, alternative technologies must be developed.

3D Concrete Printing (3DCP), when compared to traditional methods of building and construction, is well established to offer substantial reductions in terms of its carbon footprint, operational lead time, and associated costs. Considering the unique characteristics of 3DCP structures, which can be constructed with a hollow lattice-designed cross-section, they inherently offer a larger surface area exposed to CO2 compared to solid cast concrete. Moreover, adjustments in print parameters such as layer height or stand-off distance can further optimize the material's compaction and porosity, which are crucial for achieving CO2 ingress and mineralization objectives. Therefore, the simultaneous introduction CO2 gas while altering these parameters may prove to be a more efficient and complementary approach to 3DCP, potentially surpassing the limitations of post-chamber curing techniques.

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)

7e6fdc03-9018-4d08-9a98-8a21acbc37ba.tmb-mega-menu.jpg?Culture=en&sfvrsn=7deaf618_1)