Seminar on AI/ML Directed Polymer Materials and 3D Printing

Professor Rigoberto Advincula Governor's Chair Professor and Group Leader Oak Ridge National Laboratory and University of Tennessee This seminar will be chaired by A/P Hortense Le Ferrand. |

| Seminar Abstract |

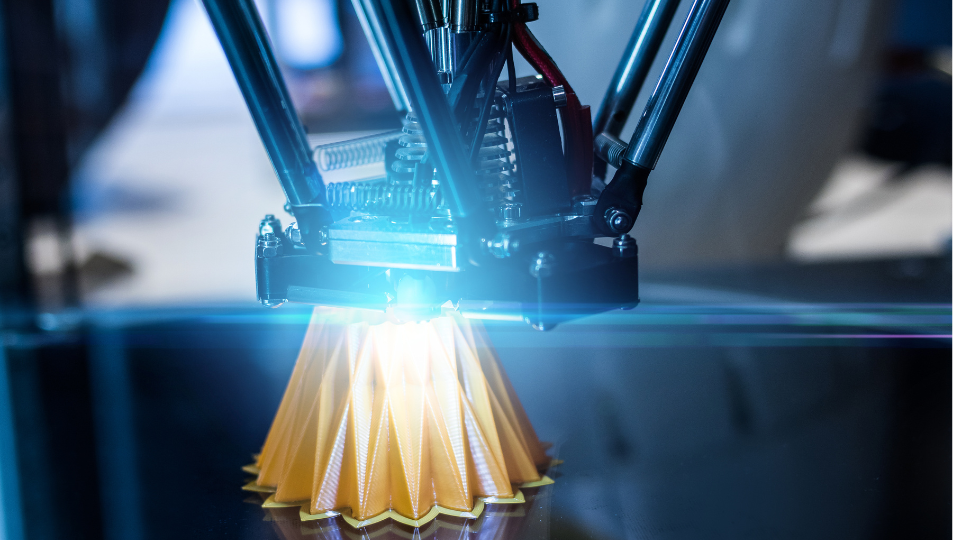

Background and Objectives: Creating and curating new data appends the way we approach materials science. In additive manufacturing (AM), the fabrication of parts and objects with high complexity and high performance is advantageous over other methods. Using nanocomposites enables highly improved properties even with “commodity polymers” that do not need to undergo high-temperature processes or extensive reformulation. With artificial intelligence and machine learning (AI/ML), optimizing the formulation and manufacturing methods is possible. Using sensors capable of a feedback loop mechanism and the ability to use simulation to create digital twins, optimizing properties in record time is possible. Methods: Beyond statistical and logic-derived design, including regression analysis, are starting points for designing experiments (DOE) or principal component analysis (PCA) in optimization we have utilized ML to enable better experimental parameters towards high performance. We have demonstrated this in two examples: 1) synthesis protocol for copolymers for 3D printing, and 2) ML Methods for optimization of 2D nanomaterial dispersions in piezoelectric sensors. Results: We thus demonstrated the approaches toward understanding nanostructuring in composites optimization via AI/ML and other training/learning sets for specific properties and applications. 3D printing enabled quadrupling of the piezoelectric behavior of PVDF. The use of 8 wt% nanomaterial loading resulted in up to 8x improvement in sensitivity as a piezoelectric sensor. Digital workflows and ML in flow chemistry reactions was made possible by introducing more sensors (monitoring instruments) in the optimization processes and real-time ML with online monitoring allows a feedback loop control. Discussion and Conclusion: This work has resulted in a greater understanding of the nanostructuring in composites and hierarchical approaches in optimization via AI/ML and 3D printing. This has also been demonstrated in continuous flow chemistry reactions. ML with online monitoring feedback loop control should open the way for deep learning (DL) in autonomous fabrication and data analytics. |

| Speaker's Biography |

Dr. Advincula is a Governor's Chair Professor and Group Leader at Oak Ridge National Laboratory and University of Tennessee. His research and group interests are: design, synthesis, and characterization of polymers and nanomaterials capable of controlled-assembly, nanostructuring, and self-organization in ultrathin films and monoliths. This includes functional macromolecules, coordination polymerization, polymer brushes, electropolymerization, and preparation of nanoparticles and hybrid materials. Properties include: smart coatings, stimuli-responsive, toughened, conducting, energy translating, optically active, or biocompatible. Surface sensitive spectroscopy and microscopy is systematically utilized to probe materials properties at interfaces. They are also involved in investigating nanoparticles, nanostructured surfaces, nanocomposite materials, 3-D printing, coatings, biomaterials, and process development. Dr. Advincula has led major projects including a fiber composite project with the DOE, EERE, AMO. He has a number of major awards with the American Chemical Society (ACS) and Fellow Honors; FRSC, FIMMM, NATAS Fellow, PMSE Fellow, Poly Fellow. Most recently he received Fellow status with the National Academy of Inventors (NAI) and the International Prize of the Society of Polymer Science of Japan (JSPS). He is most passionate in mentoring young minds in to the STEM disciplines. |