When fun is the family business

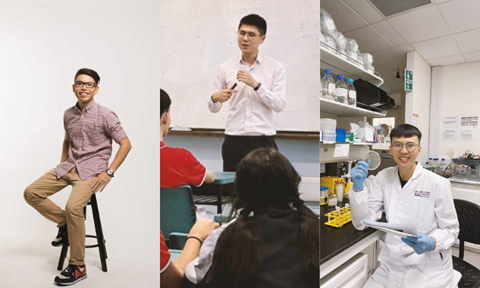

With knowledge and experience gained from his minor in entrepreneurship, NTU mechanical engineering grad Cheang Kar Wai brings an entrepreneurial mindset to a family business that designs and builds customised playgrounds.

Text: Foo Jie Ying

To most kids, the playground is their haven, and Cheang Kar Wai (MAE/2012) was no exception growing up.

“When I got to know that my dad actually builds playgrounds for a living, I thought it was the coolest job in the world,” says the 35-year-old. “That was when I became interested in the business.”

In 1984, Kar Wai’s father founded Semec Enterprise, which started off manufacturing and supplying sports and fitness equipment. A decade later, the company ventured into playground equipment.

Some of Kar Wai’s earliest memories of his father’s work are of weekends and school holidays spent at his father’s factory in an industrial district in Woodlands.

Later, in his teenage years, he started tagging along to his father’s site visits and overseas trade shows, gradually learning the ropes from him.

Upon graduation, the mechanical engineering graduate joined Semec in 2013. Taking a minor in entrepreneurship prepared him well for the late nights to come. “The late nights are reminiscent of the ones I spent rushing for project deadlines back in school,” says Kar Wai.

He also learnt more about teamwork and interpersonal skills through the minor programme. These skills have come in handy as he worked his way up to become the company director.

Kar Wai now leads a team of 45 – including three NTU alumni trained in product design – to execute playground projects at Semec. His father remains the managing director.

Today, the homegrown playground contractor is behind some of Singapore’s most popular playgrounds and many others found in housing estates, parks, and condominiums. This includes Singapore’s largest playground, at Admiralty Park, and its tallest, Coastal PlayGrove at East Coast Park. And if you’ve visited Bird Paradise with your kids, they might have played at its playground at the west arrival node.

With a few other major projects in the pipeline, Kar Wai is now working on a game plan that will help the business meet its next milestone: fabricating playground parts in-house, which he believes will take the company to the next level.

“This will allow us to have greater flexibility in design,” he says, noting that most new playgrounds, such as the ones the company will be installing in the Tengah housing estate, called for customised designs.

While Kar Wai is in the business of fun, he is quick to point out that building playgrounds is no child’s play – the play areas have to be fun and safe at the same time. “Now that I am a parent, I have started to wonder how we can make the design even safer for children,” adds Kar Wai, whose daughter turns two in October. The process starts with designing and endless rounds of revisions to configure the structure and ensure that it complies with safety standards, before working with international partners to fabricate the equipment and piecing them together on-site.

“When new parks and play areas are opened, people might be wowed by them but they wouldn’t be aware of the long process behind the scenes, from designing and manufacturing to installation,” he says. “Sometimes, our designers only see their projects come to life four or five years later.”

Related stories:

This article first appeared in issue 3 of U, the NTU alumni magazine.