NTU Singapore scientists develop smart technology for synchronised 3D printing of concrete

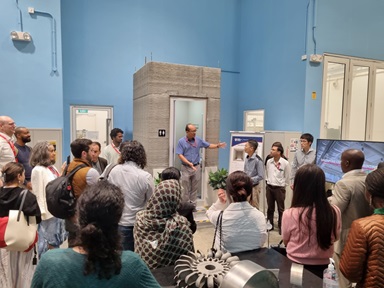

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a technology where two robots can work in unison to 3D print a concrete structure. This method of concurrent 3D printing, known as swarm printing, paves the way for a team of mobile robots to print even bigger structures in future.

Developed by Assistant Professor Pham Quang Cuong and his team at NTU’s Singapore Centre for 3D Printing, this new multi-robot technology was published in Automation in Construction, a top tier journal for civil engineering. The NTU scientist was also behind the Ikea Bot earlier this year where two robots assembled an Ikea chair in 8 mins 55s. “We envisioned a team of robots which can be transported to a work site, print large pieces of concrete structures and then move on to the next project once the parts have been printed,” explained Assistant Professor Pham from NTU’s School of Mechanical and Aerospace Engineering. “This research builds on the knowledge we have acquired from developing a robot to autonomously assemble an Ikea chair. But this latest project is more complex in terms of planning, execution, and on a much larger scale.”

Professor Chua Chee Kai, Executive Director of the Singapore Centre for 3D Printing said disruptive Industry 4.0 technologies like additive manufacturing, can be advanced even further when combined with other innovative technologies like robotics, artificial intelligence, materials science and green manufacturing techniques. “This multiple robot printing project is highly interdisciplinary, requiring roboticists to work with materials scientists to make printable concrete. To achieve the end result of a strong concrete structure, we had to combine their expertise with mechanical engineers and civil engineering experts. Such an innovation demonstrates to the industry what is feasible now, and prove what is possible in the future if we are creative in developing new technologies to augment conventional building and construction methods.”

This research project was supported by the National Research Foundation, Singapore (NRF Singapore) and Sembcorp Design and Construction, one of the key industry research partners of SC3DP. Moving forward, the NTU research team will look at integrating even more robots to print larger scale structures, optimising printing algorithm for consistent performance and to improve the concrete material for faster curing.

Media article

- Media Release, 2 Oct 2018

- New Atlas, 2 Oct 2018

- 3D Printing Media Network, 3 Oct 2018

- 3D Print, 3 Oct 2018

- Tech Explorist, 2 Oct 2018

- Science Daily, 2 Oct 2018

- Tech Site, 2 Oct 2018

- Tech Revolutionist, 4 Oct 2018

- Enterprise Innovation, 4 Oct 2018

- Create Digital, Australia, 9 Oct 2018

- Sing Tao Daily (USA), 6 Oct 2018

- Global Construction Review, 4 Oct 2018

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)

7e6fdc03-9018-4d08-9a98-8a21acbc37ba.tmb-mega-menu.jpg?Culture=en&sfvrsn=7deaf618_1)

.tmb-listing.jpg?Culture=en&sfvrsn=79414a42_1)

.tmb-listing.jpg?Culture=en&sfvrsn=44a7760d_1)