Electronics

Facile Synthesis of 3D Graphene Flowers for Ultrasensitive and Highly Reversible Gas Sensing

Principal Investigator : MAE, A/P Miao Jianmin

Key Features and Innovation

- Flowerlike graphene architectures with an average size of more than 10 μm have been successfully prepared directly on Ni substrate by MPCVD for the first time.

- Furthermore, the synthesized GF are exploited as an ultrasensitive NO2 sensor with ultrafast recovery and good reversibility. The extremely high sensitivity of 133.2 ppm-1 is obtained, and the theoretical LOD of 785 ppt is achieved.

- Importantly, the GF sensor takes as little as 2 s to reach 90% conductance recovery and spends only 20 s to achieve 100% recovery, indicative of ultrafast and full recovery.

Potential Application

- The work provides new insight in synthesizing Gr in a cost-effective and high-yield fashion via MPCVD for gas sensing with high-performance, including ultrahigh sensitivity, good reversibility, selectivity and reliability.

Relevance to which Industry

- Air quality monitoring

- Chemical sensing

Figure 1. (a) Schematic illustrating the principle of synthesizing GF by MPCVD.

(b) Photograph showing the setup of homemade MPCVD, in which a microwave oven is utilized. The plasma can be seen clearly inside the microwave oven.

(c-e) SEM images showing a continuous network of 3D interconnected flower morphology of Gr grown on Ni foam. GF cover the walls of the foam-like Ni substrate.

(f) TEM image of peeled Gr sheets reveals a rolled-up layered Gr structure.

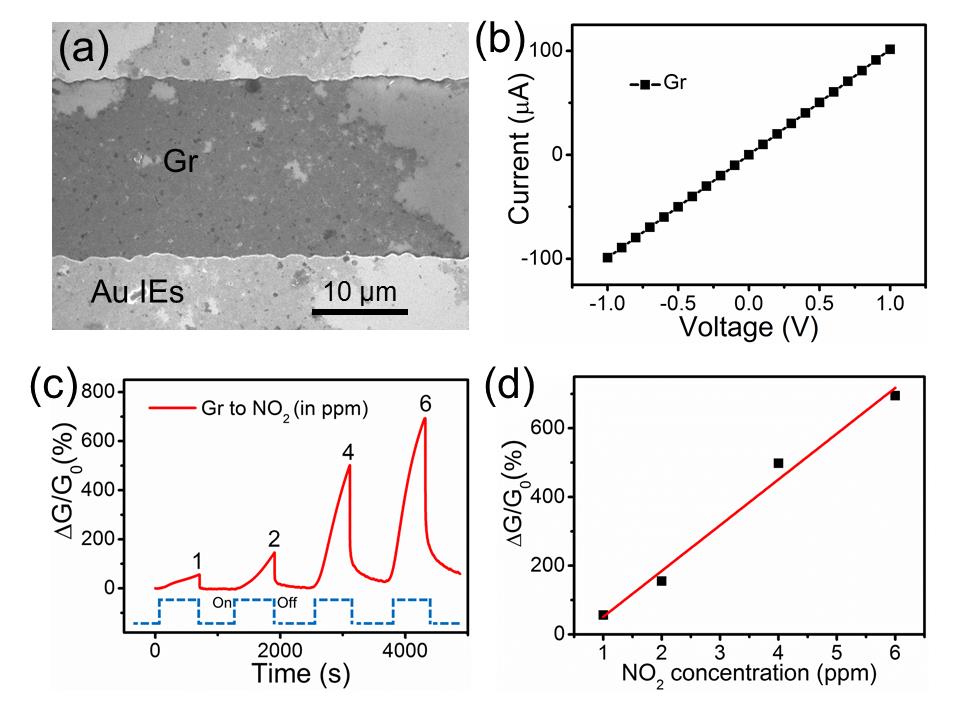

Figure 2. The Gr-based chemiresistor-type NO2 sensor.

(a) SEM image showing one of the gaps on the Au IEs was bridged by Gr sheets. The black and white regions in the gap correspond to Gr layer and substrate respectively. (b) Current versus voltage curves of the Gr-based sensor. (c) Dynamic response of the Gr sensor versus time upon exposure to NO2 with concentration increased from 1 to 6 ppm. The blue dashed line denotes the on/off states of test gas. (d) Response variation of the Gr sensor versus NO2 concentration.

Figure 3. (a) and (b) Dynamic and quantitative sensing responses of the Gr sensor to various gaseous chemicals respectively, including 70% RH, 20 ppm CO2, 5 ppm NH3, saturated methanol, ethanol, acetone, toluene, dimethylformamide, hexane vapors and 100 ppb NO2. Responses of all chemicals were obtained at room temperature except that of 70% RH was measured at 50 °C.

Large Engineering Simulation for Complex Adaptive System (LesCaS)

Principal Investigator : SCSE, Prof Ong Yew Soon

Key Features and Innovation

- Offers intelligent decision support, analytic and optimization system for supporting large-scale real world engineering problems such as urban transportation and supply chain governance.

- LesCaS can deal with complex problem dynamics through native modelling and simulation capabilities, or be extended and built upon in customized system implementation and integration of turnkey solutions.

Potential Application

- To date, LesCaS has been involved in the development of nature-inspired business intelligence solutions that has been successfully applied in the field of logistic scheduling, organizational planning, urban transportation, supply chain management, intelligent games and animation platforms such as the flocking animation and modeling environment, examples of use in real world implementation:

- Computational Labour Economics Firm (CLEF) builds upon LesCaS to enable micro- and macro-level analytics to support labor market management and other strategic decision making tasks in large organizations

- Neuro10 builds upon LesCaS to enable advanced analytics and machine learning capabilities that specialize in machine and network data

Relevance to which Industry

- Information and Communications

- Manufacturing

- Transportation and Storage (Logistics)

- Wholesale and Retail, etc

Figure 1. Screenshot of Vehicle Routing feature in a Supply Chain Management System built with LesCaS

Figure 2: Screenshot of a cloud-based Logistics Modelling and Simulation System built with LesCaS (easily accessible via web browsers)