CICS, Centre for Integrated Circuits and Systems

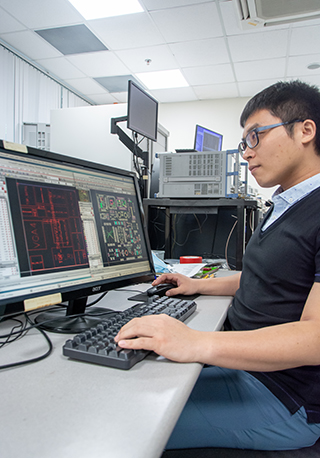

What we doCICS, Centre for Integrated Circuits and Systems is jointly funded by Nanyang Technological University (NTU) and Singapore Economic Development Board (EDB) (previously named VIRTUS), aims to be a world-class IC design house, developing key

technologies required to design integrated circuits and systems for applications in medical technology, clean technology and consumer electronics. The centre brings together key actors from IP, fabless, semiconductor, system houses and design industry

to build a vision of the next step in analog/digital/mixed integrated circuit and system design. The centre’s research activities can be broadly divided into the following major areas, namely analog, mixed‐signal, power management and data converters;

energy harvesting; low‐power RF and mm‐wave ICs; and new technology directions such as 3D‐integration and physical design; 3D RF and mixed‐signal circuits; and terahertz ICs etc..

The set up of CICS is in line with Singapore’s

four new growth areas in the electronics sector - green electronics, bioelectronics, plastic electronics and security. In the near future, consumers can look forward to electronic devices such as laptops, PDAs and mobile phones that are ultra-low

powered or self-powered. This is made possible with power management and energy harvesting technologies which are critical elements for power optimisation and higher energy efficiency in electronic devices and systems.

Seven top American,

European and Chinese universities have signed memoranda of understanding with CICS to collaborate in joint research in IC design. These seven universities are University of Michigan; Purdue University; University of California, Los Angeles, or

UCLA; Technical University Munich; Linköping University; Zhejiang University; and Fudan University.

Besides academic collaborations, CICS has also forged close partnerships with leading industry players including Mediatek,

Agilent Technologies, Verigy, SiliconCore Technology, United Microelectronics Corporation, Infineon, Broadcom Corporation and A*STAR Institute of Microelectronics. In addition, six organisations have pledged to contribute five-and-a-half million Singapore

dollars to CICS to carry out advanced IC design research. The six are A*STAR Exploit Technologies Pte Ltd, Infineon, Mediatek, SilconCore Technology, Systems on Silicon Manufacturing Company and Verigy.

CICS will continue to

establish joint collaboration with world renowned universities, top research institutions and well-known companies in its pursuit of excellence in research and development in IC design and technology.

Research Focus

The centre's research focus on the following 5 main areas:

1. Analog, Mixed-signal, Power Management and Data Converters

2. Memory and Advanced Techniques in Nano-scale CMOS

3. RF and mm-wave

4. Smart Sensors

5. Technology Direction and System Integration

Our News

Read more newsPrinting electronic devices at home is now closer to reality

VIRTUS, IC Design Centre of Excellence at School of Electrical and Electronic Engineering (EEE@NTU) have developed a new way to print complex electronic circuits and systems using fully-additive processes. Their unique method is environmentally-friendly, low cost and scalable compared to subtractive or mixed processes, and produces components with high semiconductor carrier-mobility.

Printed electronics are usually thin, light and flexible, and can be used for, say, intelligent labels that track if milk cartons have been stored in required temperature ranges.

The field is dominated by subtractive-based processes such as laser ablation, where lasers are used to remove material from a solid. These processes, however, require specialised and expensive equipment, use corrosive chemicals and squander material. Other scientists’ attempts at fully additive processes, which involve only depositions onto a film, resulted in components with low printed semiconductor carrier-mobility, which would severely limit devices’ speed.

The EEE technique uses widely available silver paste, which has high electrical and thermal conductivity, for electrodes. The silver electrode is dipped in pentafluorobenzenethiol solution which increases its work function and overcomes the low carrier-mobility problem.

The researchers also used slot die coating to print the semiconductor layer. This results in fewer crystal grain boundaries, which quickens electrons’ flow, further increasing devices’ speed.

The technique can print passive elements including capacitors, resistors, inductors and two metal interconnect layers – to date, the only fully-additive process that can realise complex circuits and systems on flexible plastic films. To demonstrate its commercial viability, the researchers printed one proposed and two conventional differential amplifiers, and a 4-bit digital-to-analog converter.

The team also developed a comprehensive printed transistor model that is simple, accurate and compatible with industry-standard integrated circuit electronic design automation tools. This model allows manufacturers to simulate potential printed transistors’ operation, which is crucial for to design practical printed electronic circuits.

The researchers showed that, by using an appropriate layout, the mismatch between printed transistors can be reduced to a relatively low 8%, despite variations of up to almost 40% between inpidual transistors.

Dr Ge Tong, a senior research fellow at School of EEE, said: “What manufacturers get from the simulator will be very close to what they get if they print the actual circuit.”

- Interviews

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)