Singapore firm NivéSal forges new partnerships to boost manufacturing in Africa

Managing Director Saikat Chowdhury wants to plug the information gap that inhibits domestic manufacturing from taking off

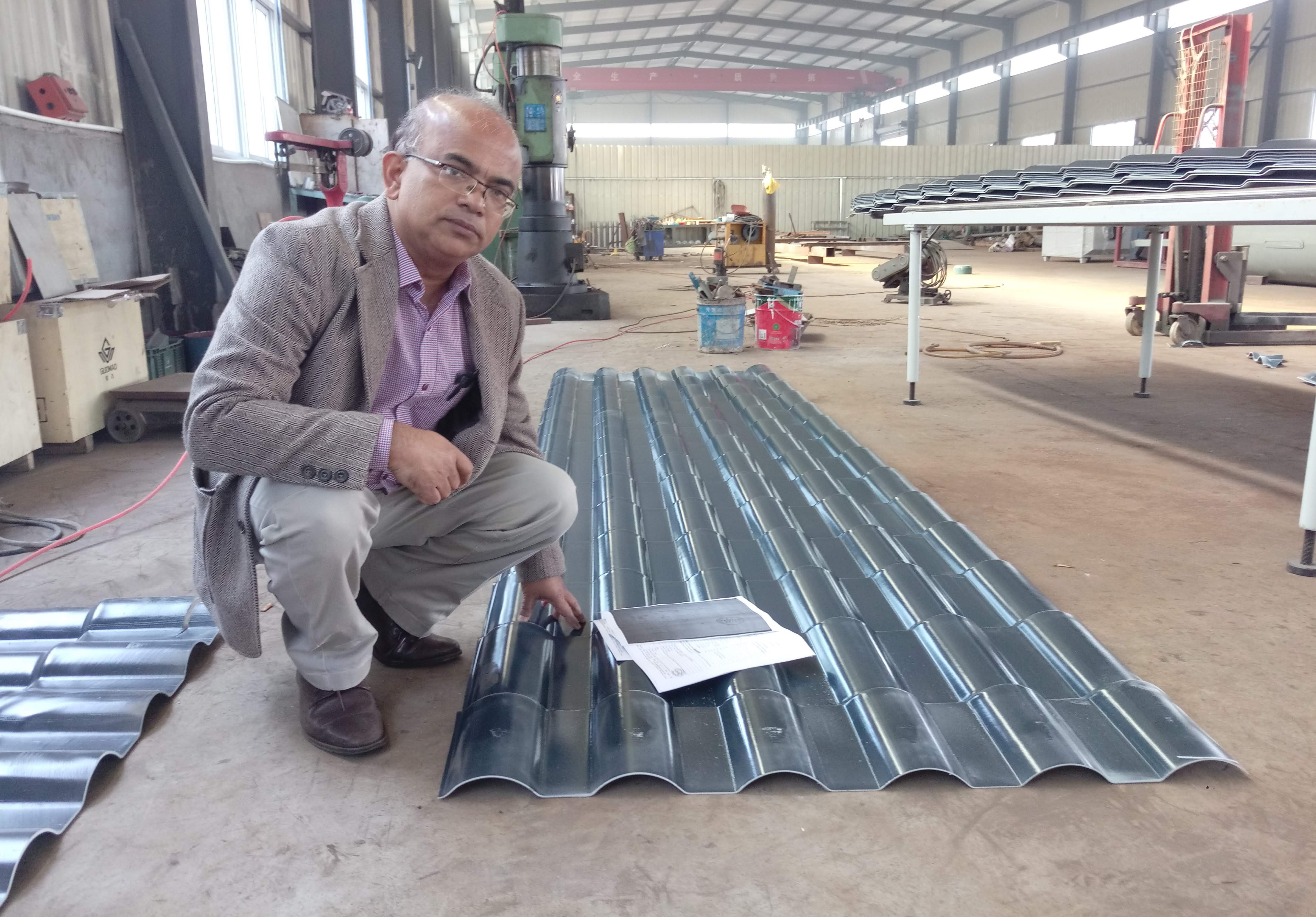

NivéSal's Managing Director Saikat Chowdhury testing the PVC roofing sheet before installation in Rwanda

NivéSal's Managing Director Saikat Chowdhury testing the PVC roofing sheet before installation in Rwanda

In a groundbreaking development at the recent Africa Singapore Business Forum (ASBF), Singapore-based engineering firm NivéSal signed a series of critical memoranda of understanding with relevant counterparties from Ghana, Sierra Leone, and Kenya to aid the development of the manufacturing sector.

NivéSal specialises in providing services tailored to the needs of small to medium-sized industrial ventures across various sectors, including food, consumer goods, and building materials. Their comprehensive range of services encompasses project assessment, equipment provision, installation, commissioning, and staff training.

The highlight of the forum was NivéSal's agreement with Ghana's dynamic SKY 40-40 to establish a cutting-edge polymer-based building materials manufacturing venture in the thriving port city of Takoradi. Saikat Chowdhury, Managing Director of NivéSal, said that SKY 40-40, traditionally involved in sectors such as transportation and mining, has expressed a compelling interest in the realm of manufacturing, leading them to approach NivéSal. Chowdhury believes that African manufacturing sector is at an inflection point. The decline in the manufacturing sector’s share of African GDP appears to have bottomed out. Although the continent currently contributes less than 2% to global manufacturing, the manufacturing sector itself accounts for almost 12% of the continent’s GDP, which is more or less, equivalent that of India - a rising manufacturing centre. African consumer demand is anchored on a young and growing population and is slowly shifting towards more processed goods, which is growing at 1.5 times faster than the global average. According to Chowdhury local traders and distributors are, therefore, willing to consider branching into manufacturing but they remain hesitant, mistakenly perceiving manufacturing as overly complex and costly. He says, that is a myth that needs to be broken. 61% of African imports are manufactured goods. Many of the imported goods can be manufactured locally, he claims. He illustrated this with an example, pointing out the lack of a central resource for local entrepreneurs seeking comprehensive guidance on starting a manufacturing venture, such as a biscuit factory. It is local entrepreneurs, not foreign investors, who are driving SME manufacturing of essential goods in Africa. Yet, there remains the absence of adequate structural support for such entrepreneurs.

In Sierra Leone, NivéSal has secured a significant deal for a cement manufacturing project from a local cement importer and distributor. Chowdhury noted that, contrary to the norm where African cement producers source equipment from Europe, NivéSal is strategically planning to source equipment from India, anticipating a cost reduction of up to two-thirds compared to European suppliers.

In Kenya, NivéSal has taken a proactive step towards bridging this information gap by signing an agreement with the Kenya Investment Authority to provide technical guidance for launching various manufacturing ventures at no cost. The firm’s revenue model is dependent on local entrepreneurs seeking a further collaboration with Nivesal on commercial terms. Kenya's manufacturing sector, according to Chowdhury, stands ahead of many African countries. Still, there remains untapped potential for local brands, especially in product categories like pasta, noodles, soaps, and detergents.

Chowdhury says that aspiring consumer goods manufacturers in Africa do not necessarily require extensive manufacturing lines. Most African markets cannot accommodate large-scale production volumes, necessitating investments in appropriately sized facilities. Additionally, given the abundance of labour in Africa, not all manufacturing processes need full automation. Chowdhury illustrated this with a soap manufacturing scenario, where he proposed partial automation up to the point of sealing soap bars, ensuring quality, while the subsequent product packing into cartons would be done manually. By customising manufacturing processes in Africa to align with market-specific needs, significant cost reductions can be achieved without compromising product quality.

Chowdhury's visionary approach, combined with strategic collaborations, exemplifies the promising prospects for reviving and boosting Africa's manufacturing sector. With these initiatives, there is a tangible opportunity to transform Africa into a global manufacturing hub and drive economic growth across the continent.

References

‘Africa Industrialization Index 2022’, African Development Bank Group, 24 November 2022

‘Five new business deals signed as more Singapore firms respond to call of Africa', The Straits Times, 29 August 2023