Lead Free Solders for Fine Pitch Interconnects

Investigators: Prof Chen Zhong, A/P Thirumany Sritharan, A/P Wong Chee Cheong & Prof Subodh Mhaisalkar

Solder joining is one of the most popular interconnection methods in microelectronic packaging. Intermetallic coumpounds (IMCs) are formed between the solders and the under-bump metallization during the joining process. The reliability of solder joints is determined by the strength and morphology of the solders, the interface between solder and the IMCs, and the IMCs themselves. Several projects are underway to examine various aspects of joint reliability.

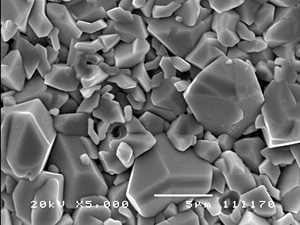

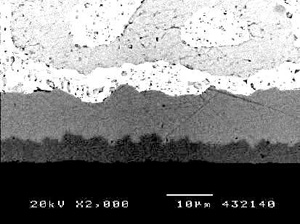

One project examines two aspects of the IMCs at the solder/UBM interface: the morphology - interface property relationship, and the mechanical properties (fracture toughness, fracture strain) of the IMCs. The fracture strength of IMCs is the least studied aspect due to the difficulty of measuring it in such thin layers consisting of nano- or micron-sized grains. Effects of processing conditions on the morphology of intermetallic compounds are being studied. The information in turn will be used to correlate to the mechanical integrity of the interface. Interfacial fracture mechanics tests will be designed and carried out. The properties to be measured include interfacial fracture toughness and interfacial fatigue life curve in the Paris sense.

Another project addresses the fundamental mechanisms of intermetallic growth at the interface with the aim of identifying the critical external factors. By analysing the IMC growth kinetics, in particular the activation energy and the time exponent, the controlling mechanisms could be identified and, consequently, attempts could be made to predict and control the growth. An understanding of the relationships between IMC morphology/thickness and the mechanical properties of the joint could eventually lead to predicting the behaviour of the whole joint.

Substantial data had been generated with Cu, and Ni coated Cu, substrates with leaded and lead-free solders. New projects are being initiated with the common substrate in chip scale packaging i.e. Au. Au has a very high solubility and diffusion rate in solders compared to Ni and Cu. Thus, interface reaction between Sn and Au is a more worrying reliability issue in chip-scale packaging.

Other projects to understand the physical metallurgy of Pb-free solders, and to modify their compositions to benefit reliability are also underway.

Ni3Sn4 intermetallic compound at the interface

Ni3Sn4 intermetallic compound at the interface

Double IMC layers at Cu-solder interface

Double IMC layers at Cu-solder interface

/enri-thumbnails/careeropportunities1f0caf1c-a12d-479c-be7c-3c04e085c617.tmb-mega-menu.jpg?Culture=en&sfvrsn=d7261e3b_1)

/cradle-thumbnails/research-capabilities1516d0ba63aa44f0b4ee77a8c05263b2.tmb-mega-menu.jpg?Culture=en&sfvrsn=1bc94f8_1)

7e6fdc03-9018-4d08-9a98-8a21acbc37ba.tmb-mega-menu.jpg?Culture=en&sfvrsn=7deaf618_1)